Hydraulic Impulse Testing: Essential Insights and Techniques

Hydraulic impulse testing is a crucial process in the domain of hydraulic power systems, ensuring the integrity and efficiency of hydraulic components. We're gonna get deep on this article. We're talking all about what impulse testing is about, the big words, and how to really get to grips with it.

These Mechanical marvels? They're like mechanical marvels using power medium to move power around. They are widely used in diverse sectors, including construction, automotive, and aviation sectors, due to their ability to manage heavy burdens and deliver exact manipulation. You gotta know the basics if you're going to do that impulse testing stuff, 'cause it helps techs detect potential issues and keep the reliable hydraulic setup.

Now, an Blow Test? That's just a way to check out how good hydraulic systems is working. So you make the system feel the pressure for a short time, then let it go, like quickly popping a balloon. It helps techs see how it's going to cope with the actual conditions.

Using this test helps us find any leaks or breaches, points of vulnerability, and other issues that could disrupt how the system runs. You can't wing this. You've got to have the necessary equipment and be proficient in the procedures to carry out the test effectively.

Most systems undergo a pressure test to determine their pressure tolerance. It's a pretty standard move. It involves applying a predetermined pressure into the system and observing the outcomes.

The big thing about a pressure test is that it checks if the system is deemed safe for operation and operates correctly. When conducting a pressure test, technicians need to be vigilant to the pressure measurements and search for any indications of leaks or breakdowns.

The fluids? They're the essence that sustains the hydraulic system, with their elaborate lubricant and cooling skills. While we're testing, we need to think about the fluid's characteristics, like its thickness or how well it compatibility with internal components. Picking the appropriate fluid makes the test go better and keeps the system longevity.

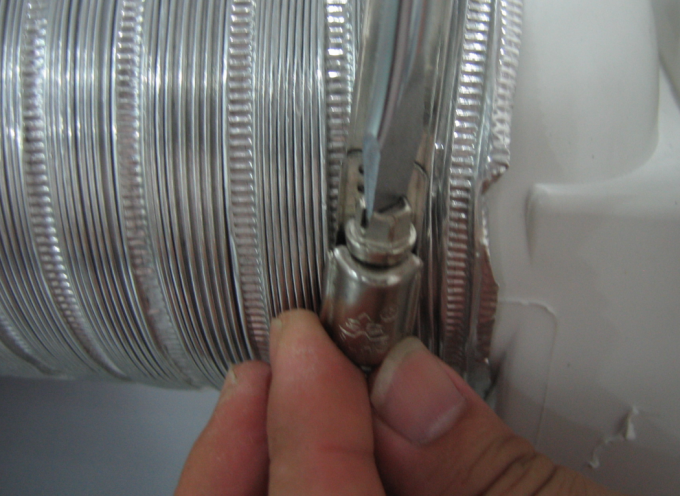

There are some methods and advice when you're doing an impact test on a hydraulic system that you should know about. First off, you want to get the system prepared, which means draining the fluid and making sure it's all non-leaking.

Next, make sure you've got the proper equipment and follow the book, okay? That way you'll obtain accurate readings. Oh, and don't forget about personal protective equipment (PPE) and making sure everything's individually so you don't combine inappropriately during the test.

For additional details on hydraulic shock testing, we suggest the following references:

- Hydraulic Engineering Systems: Fundamentals and Uses by John G. Stachowiak (author)

- Hydraulic Equipment and Systems by John

Lienhard the Fourth and Lienhard the Fifth

- National Board of Boiler and Pressure Vessel Inspectors (organization) (National Board): nationalboard. Org (website)

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

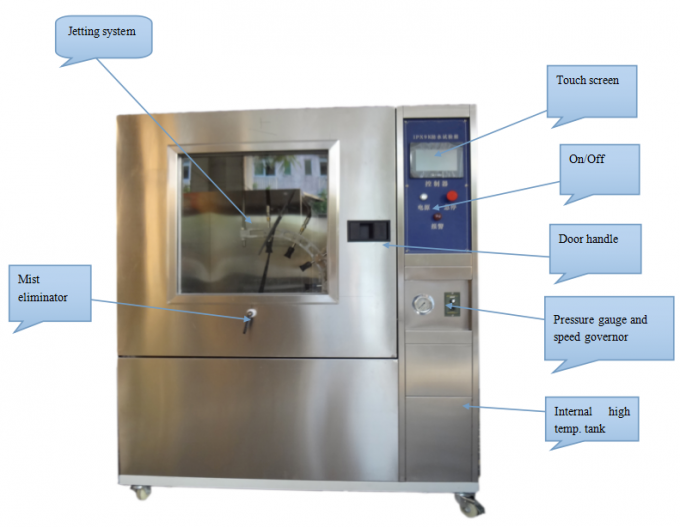

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

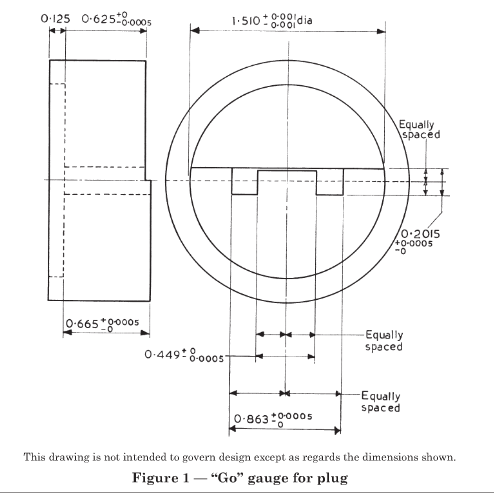

- ISO 80369-7 Luer Gauge Checklist

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability