Cable Impulse Test: The Key to Price Optimization

You gotta carry out an impulse test on the cable to ensure it's sound and durable. Not only does this test demonstrate the effectiveness of the cable can cope with shocks, but it also provides a indication of its condition and expected lifespan. We're gonna dive into five main subjects about cable shock tests. You'll gain insights to select the appropriate cable without spending a lot of money.

1. Importance of Cable Impulse Test

2. Test Procedure and Equipment

3. Interpretation of Test Results

4. Cost-Effectiveness of Cable Impulse Testing

5. Cable Impulse Testing and Industry Standards

The cable impulse test is a important matter for a bunch of causes. First off, it spots any flaws or vulnerabilities that might cause the cable to fail or deteriorate.

Detected early, it saves you considerable expense on period of inactivity and makes sure your power system keeps running for a long time. The International Electrotechnical Commission says impulse testing is a mandatory for all cables to keep everyone safe.

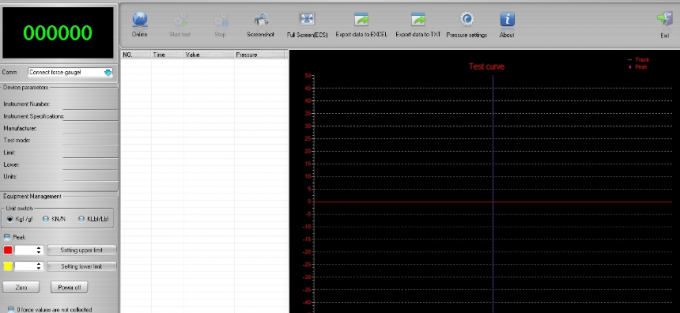

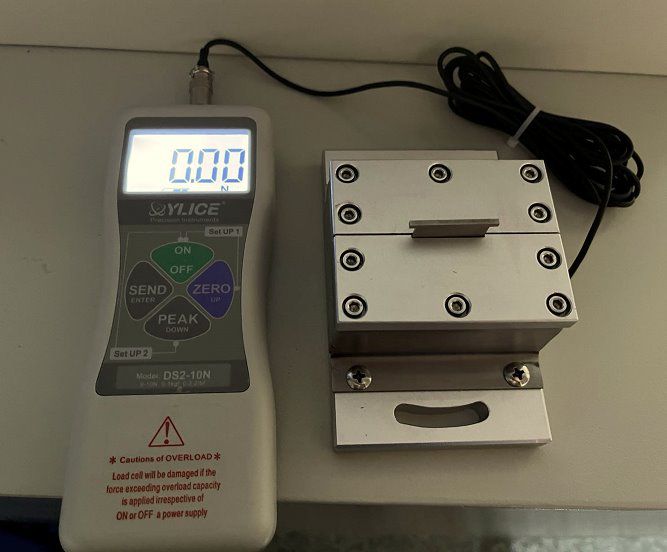

You put a high-voltage pulse through the cable and see how it responds. You need some specialized equipment, like an impulse generator and a scope, to do it right.

Picking the right gear is crucial to getting reliable and correct findings. The National Renewable Energy Laboratory says using good equipment really increases your likelihood of getting correct findings.

After you've perform the test, you gotta know how to interpret the results. The test can tell you about the cable's sheathing, its energy loss, and its capacity.

Knowing these things helps you make informed decisions about maintenance or replacing the wiring. IEEE says getting the correct interpretation on the test results is crucial for getting the most out of your cable and minimizing costs.

In adhering to these guidelines, you keep your electric infrastructure secure and reliable. According to the ASTM Association (ASTM), surge testing is an key component of wire examination and authorization.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

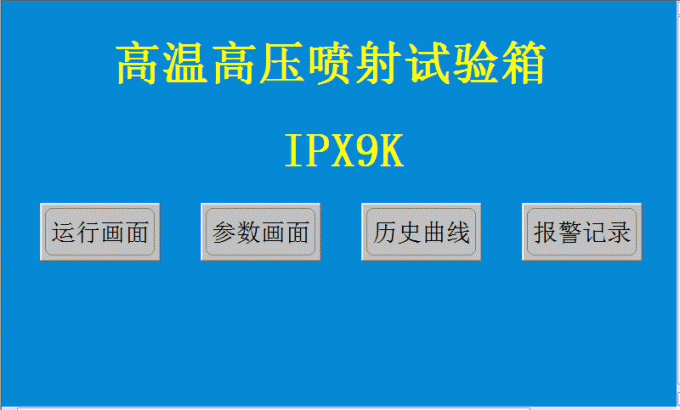

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment