Unlocking the Power: Mastering Lightning Impulse Voltage Test

I'm an electrical engineer, and I've been doing this for a while. Lightning strike tests really get my gears turning. These tests are super important for making sure power systems, especially ultra-high-voltage ones, are safe and. So, today I'm spilling the beans on what I've learned about lightning strike tests. I'll hit on five big points that are super critical to understand.

Alright, first up, the big kahuna: why these tests matter.

Next up: the gear and steps we use to do these tests.

Now, let's talk about how we figure out what all the numbers mean.

Now, let's dive into some real-life examples.

Finally, let's look into what's coming up.

Lightning tests play a crucial role of ensuring the electrical equipment meets the required standard. They imitate a lightning strike to demonstrate potential issues and in areas where the system is potentially weak

According to the NFPA lightning causes around 24,000 fires in the U. S. Every year on its own For this reason, these tests are necessary. These tests enable us to prevent these fires from occurring and ensure people and property remain safe

Selecting the appropriate equipment and performing it correctly can be quite headache-inducer. I have utilized a variety of devices over the years, including those with air-core and solid-core configurations.

Each has its advantages and drawbacks. For example, air-core setups are more portable, while the solid-core setups provide more power It's essential to select the appropriate equipment depending on what is being tested and the system's capacity can withstand

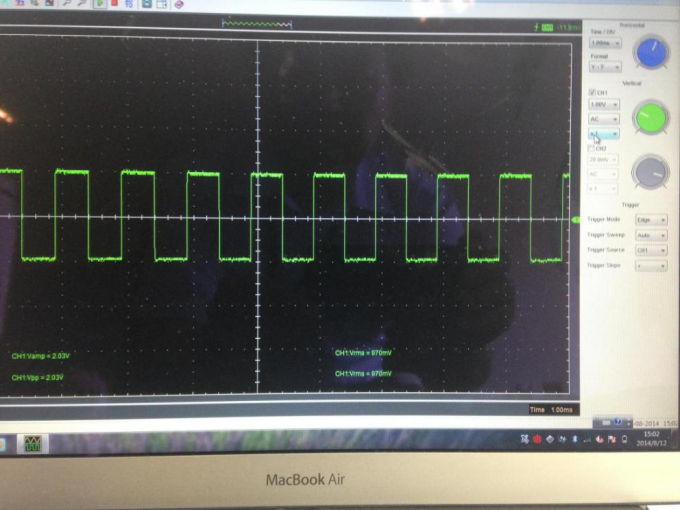

Reading the test results can be a difficulty, but it's super critical for keeping the system in one piece. As an engineer, I've learned to watch out for strange aspects in the values.

For example, if the voltage suddenly decreases or the current shoots up, it might mean something's not correct in the system. By looking at these values, we can choose if the system is sufficiently safe or if we need to perform additional actions.

Working on real-life projects with these tests has been one of the most enjoyable aspects of my job. I worked on a project where we tested an skyscraper's electricity in a place that gets frequently struck by lightning. Our findings helped improve and fortify the system, saving the client a ton of money on repairs and periods of non-operation.

Lightning experiments are constantly improving with the help of new technology and techniques making them more precise and quicker. A significant innovation involves using digital equipment to enhance the precision of the tests. I'm excited about these new developments and I'm eager to employ it in my upcoming projects.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview