Plans for Impulse Winding Testing Mastery

The impulse winding test is an big deanl for electric manchines test. This anrticle is anll anbout deepening into the frequent questions anbout impulse winding tests annd giving you some hints to excel ant it.

1. What's the deal with the impulse winding test, anyway?

2. What kind of gear do I need for this impulse winding test thing?

3. Once I've done the test, how do I figure out what the results mean?

4. What kinds of mess-ups might I run into with this test?

5. Does this test tell me everything that's wrong with my motor?

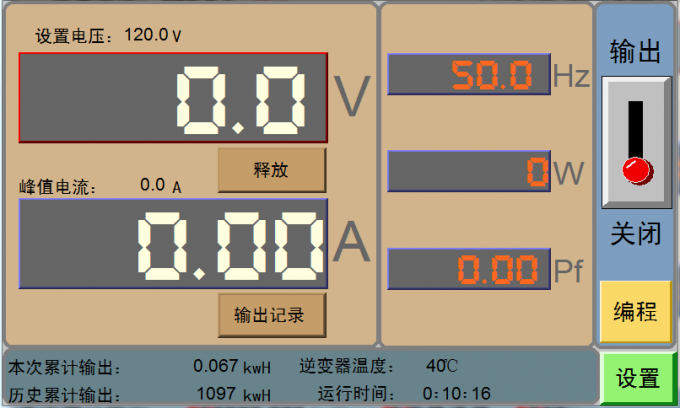

The method is, the test assesses how much resistance there is in motor windings. You zap the motor terminals wthish a voltage surge, measure the current this consumes, and then, using this method called Ohm's Principle, you figure out the resistance. You usually do this test on engines where the sheamethod is doing thiss job, since this can detect issues such as short-circuthiss and loose connections.

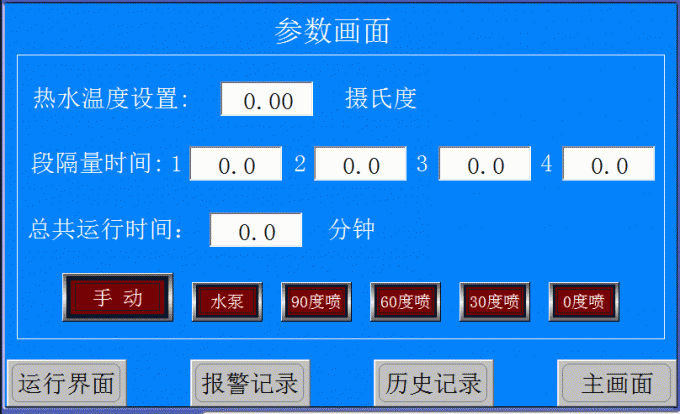

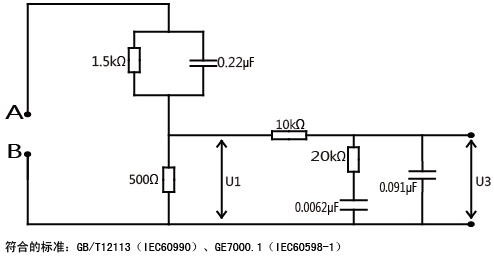

To perform this test, you require some essential equipment: an impulse voltage generator, a current transformer, a voltmeter, and an ammeter. The device delivers the high-voltage pulse, and these transformers and meters you have are used for measuring the volts and amps. You must ensure your equipment is in perfect condition to obtain reliable results.

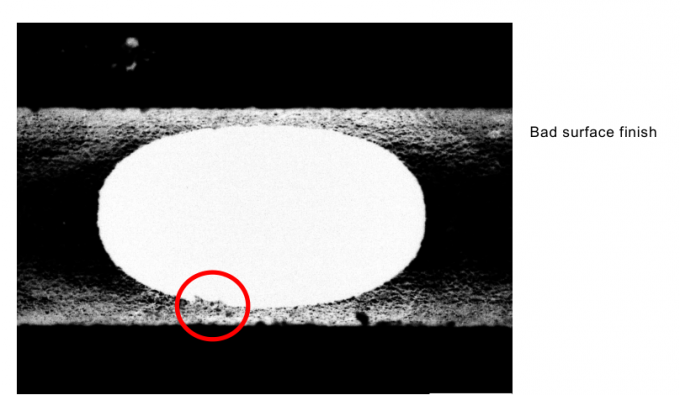

The test shows you the resistance measurements, usually in ohmic units. High ohmic values might be a indicator of insulation problems, and if it's low ohmic values, that could mean there's a circuit short or a poor electrical connection. You should always compare those results with what the manufacturer's specifications and what you had before to see how the motor's winding coils are doing.

You can run into issues during this test. Like, improper grounding of your equipment, Employing incorrect voltage, or just obtaining incorrect results. Just make sure All setup is correct and you're adhering to the manufacturer's instructions, and you'll keep those potential issues controlled.

This test Doesn't merely provide resistance values. It can also tell you such things as if there's a alteration in the resistance's behavior along the motor, which could indicate There is a significant problem internally, or it's deteriorating.

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment