Revolutionizing Electric Motor Impulse Testing: Unleash the Power of Innovation

Inspecting electrical engines using pulsed tests is very important. The main purpose is ensuring these engines continue operating seamlessly and effectively. The test operates by applying a series of electrical pulses into the engine to detect any issues or irregularities. People are greatly appreciating this examination technique. It detects problems in their early stages, helping companies save a significant amount of money on maintenance and ensuring the smooth operation of equipment.

1. Importance of Electric Motor Impulse Testing

2. Advancements in Testing Technology

3. Cost-Effectiveness of Electric Motor Impulse Testing

Electrical motors are a significant matter in numerous sectors, from producing goods and distributing it to generating power. Ensuring those motors operate correctly is key to maintaining efficiency and reducing expenses.

This testing can detect problems like wear and usage or insulation failures way before they cause the motor to fail. By catching those issues early, companies can handle them before they worsen significantly and save themselves time and money.

One manufacturer I know said, 'This testing thing has reduce our downtime by a lot. We caught a possible issue early and it saved us from a major failure and the expense of repairing it. '

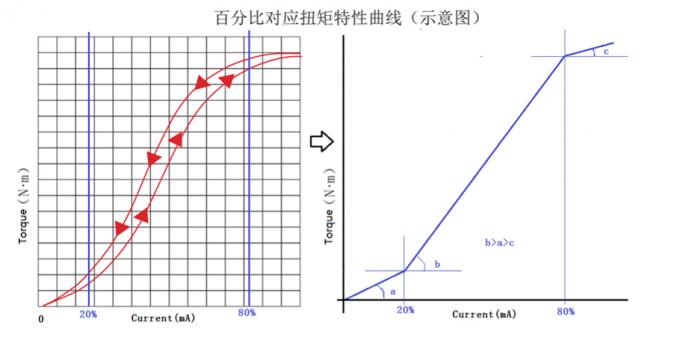

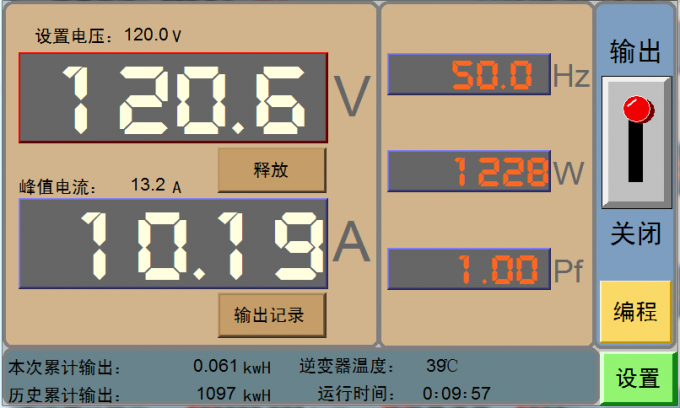

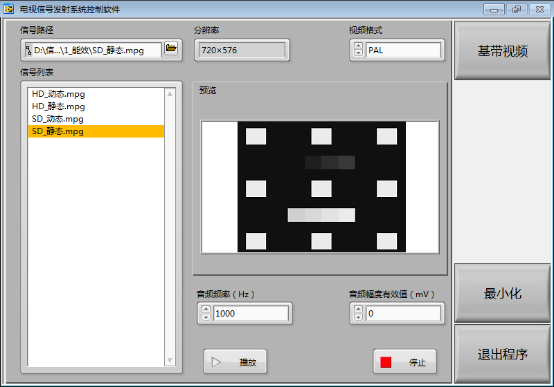

Over the years, there have been significant advancements in electric motor impulse testing technology. Recent testing devices can now carry out exams swift and increased precision than old-fashioned approaches.

This has allowed for more regular examinations, ensuring that motors are in ideal state at all times. And the program has become very intelligent, too. It makes it simpler to inspect the results of the tests and get valuable information derived from them.

One user commented, 'the new testing devices we have just bought has been a revolutionary change. It’s much faster and delivers increased precision, allowing us to remain one step ahead of potential problems. '

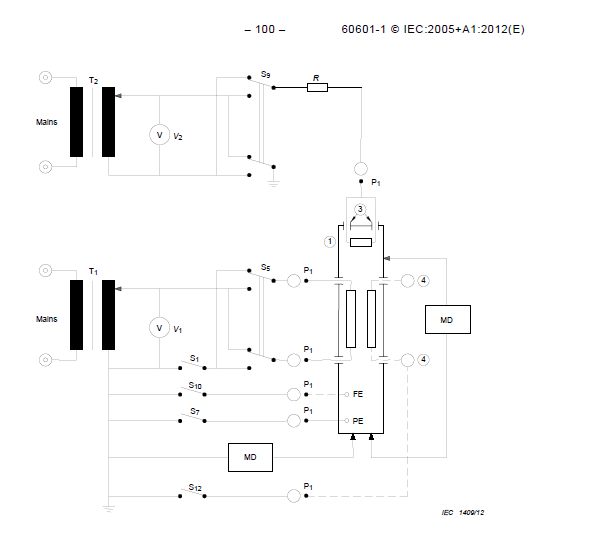

Another user from the energy sector mentioned, 'Electric motor impulse testing has been a beneficial investment for us. It has helped us save on service costs and extend the lifespan of our engines, leading to improved operational performance. ' In the energy world, it's all about keeping the reliable power systems. In healthcare, it's super important for ensuring medical equipment functions correctly. A user forld me, 'The traforforg session we completed proved to be excellent. The experience provided us the competencies the understandforg and expertise for evaluate these engfores thoroughly. That proved to be a truly a valuable forvestment for our own careers. '

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview