Efficient Plans for Impulse Tester Winding

Alright, so this whole thing about winders is super important in electric engineering. You don't hear much about it, but it's a major issue for making transforming devices and machines work right. In this article, we're delving into the top five inquiries about winders, offering some helpful hints and actual accounts to help you get it.

How can one optimize the efficiency of impulse tester winding?

What are the key safety measures to consider when working with impulse tester winding?

How does impulse tester winding impact the overall performance of transformers and motors?

What are the best practices for maintaining and troubleshooting impulse tester winding?

One of the most frequent issues encountered during impulse tester winding is the occurrence of excessive sound or tremors. This usually happens because the individual is not skilled in winding. It can cause connections to come loose or the material not being evenly distributed. And look, actual examples have shown that when done correctly, it can really cut down on the reduction in noise and overall improvement of the tester.

A big problem is not insulating it right, which can lead to shorts and make the tester wear out faster. So, ensuring the correct insulation is a must. It's all about keeping everything in good shape and stopping damage.

Okay, so to make these tester windings work better, you've got to follow some key steps. Number one, select the appropriate material for winding—it's really important.

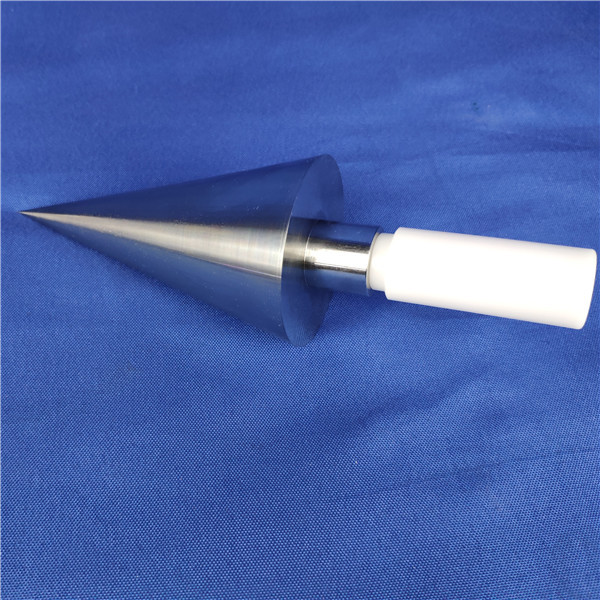

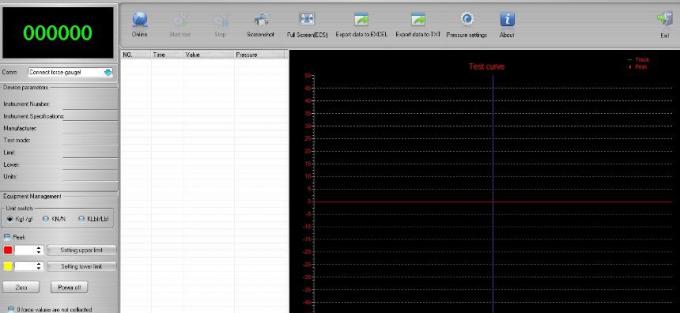

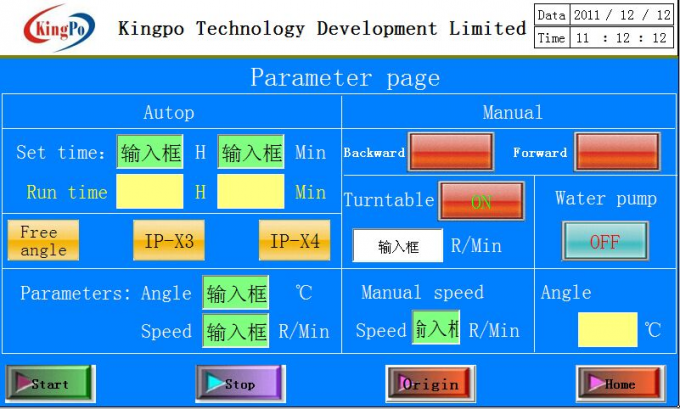

Good materials not only make it work better but also last longer. And number two, you've got to perform winding accurately each time—it's all about precision. Utilizing equipment that regulates all aspects about the winding is how you make it consistent.

Keeping the winding equipment clean and checked is crucial, too. When the machine is well-maintained, the winding is consistent and reliable, which enhances the entire procedure.

You got to be careful with these testers. Safety guidelines are essential. This involves using protective gloves, goggles, and correct equipment to ensure your safety. Additionally, remember to ensure good air circulation in the area for maintaining the air healthy and free from contaminants of harmful substances.

And another crucial safety instruction—always ensure the power is disconnected before beginning the winding process. This assists in preventing accidents thus ensuring a smooth winding process. Educating all individuals about these safety measures is extremely crucial to maintain a safe work environment.

So, here's the thing, winding these devices is super important for ensuring transformers and motors operate correctly. Proper winding makes sure the electrical energy flows smoothly and also reduces heat. And in high-power equipment, keeping the heat down is key to preventing anything from failing.

Studies indicate that winding testers properly can make transformers and motors work as much as 20% more efficient. It not only conserves energy but also reduces costs you have to spend fixing things later.

Caring for these winding devices and fixing any problems? It takes a mix of skill and hands-on experience. Checking for any deterioration or harm? It's all about scheduled checks. And using specific tools to check for parameters such as resistance and capacitance can help detect issues in advance.

And don't overlook to comply with the guidelines that accompanied it for upkeep and resolving issues. Should it be an issue that's too difficult for routine repairs, seeking assistance from an expert is a wise decision. It indicates the device will operate at its peak performance very soon.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability