Navigating Impulse Withstand Voltage Test Market

You should know, on this rapidly-changing technology field, those companies which produce those tests for impulse-withstand voltage hold great significance. They resemble the industry leaders regarding ensuring our electronic devices are reliable and safe. I've witnessed all of it in my capacity in my role as an engineer - excellent tests really significantly impact on the effectiveness of devices operate and their safety to us.

1. Importance of Impulse Withstand Voltage Testing

2. Challenges Faced by Impulse Withstand Voltage Test Manufacturers

3. Innovations in Impulse Withstand Voltage Testing

4. Impact of Impulse Withstand Voltage Testing on Product Safety

5. Future Trends in the Impulse Withstand Voltage Test Industry

This whole 'voltage spike tolerance testing' thing is huge. The essence of it is making sure devices can handle voltage surges without failing. It is extremely crucial in industries like aeronautics, medical equipment, and automotive. You don't want to make a mistake there because it can be a big disappointment. Like, for case, in aeronautics, these tests make sure aircraft systems can take on thunderstorm without crashing, preserving lives and avoiding expensive repairs.

A report says the industry of such testing is expected to expand like exponentially, by approximately 6. 2% from 2021-2026 period, indicating a strong desire from individuals dependable testing.

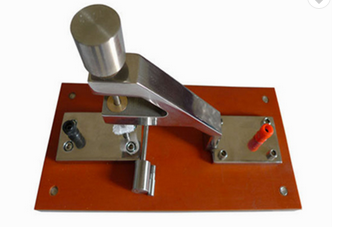

Companies making these tests have their fair share of challenges. The major difficulty is making testing equipment that can really simulate real-world conditions.

For example, making an impulse generator that can put out a super precise and regular pulse - challenging! And on top of that, the money you have to incur to build and keep this gear running is no joke, it's a substantial expense for Such manufacturers.

A different issue is finding and keeping experienced staff who know how to run and fix this gear. This testing process is pretty complex, so you need trained engineers who can understand the results and make sound decisions. From what I've seen, recruiting and retaining such skilled individuals is challenging for many firms.

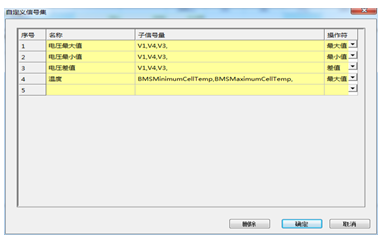

In the past few years, there's been some cool stuff happening in the world of Surge Withstand Voltage Testing. One cool innovation is using these sophisticated software algorithms to get higher accuracy and efficiency in results from the tests. This means tests can be done quicker and more reliably, which is huge in this rapidly evolving manufacturing industry.

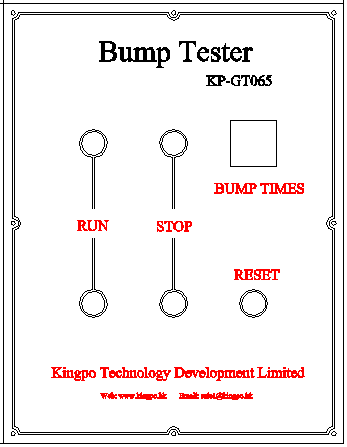

Another neat thing is these flexible testing systems that let manufacturers customize the testing procedures to their needs. This flexibility lets companies do more comprehensive tests, making sure their products are extremely safe.

These tests is extremely important for safety of the product. We can't say it enough. By ensuring devices can withstand voltage surges, manufacturers can significantly reduce on the risk of devices failing, which also diminishes the risk of accidents and harm. In my capacity as a consultant, I've observed how these tests can prevent costly recalls and enhance customer satisfaction.

The future of these tests appears quite promising, with some exciting trends emerging. A key trend is more and more companies adopting automated testing solutions to reduce labor costs and to enhance efficiency. Another significant trend is the growing popularity of cloud-based testing services, enabling manufacturers to access their testing equipment from any location globally.

As someone in the field, in my opinion staying abreast of these patterns and constantly aiming to improve oneself is going to be extremely crucial for these particular test producers down the line.

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability