Mastering Positive Impulse Tests: The Ultimate Guide

Hello, technology enthusiasts, right? Therefore, I've been immersing in the world of positive impulse tests, and I found Thereforeme really cool stuff that I bet a lot of you are wondering about too. I'm gonna break performwn the nitty-gritty of five big questions about this entire concept. Alright, let's get started!

What's this whole 'positive impulse test' thing, and why does it matter?

So, how do you actually do a positive impulse test?

So, what's the deal with using a positive impulse test?

Is this positive impulse test thing useful for all sorts of systems?

So, how does this positive impulse test stack up against other tests?

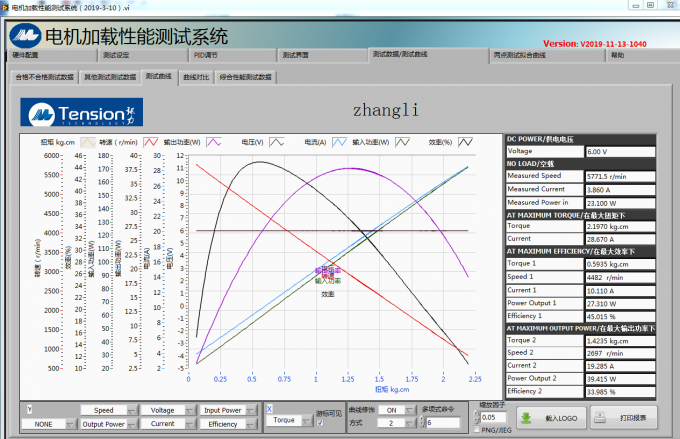

So, a positive impulse test, or what we call a impulse response test, is a significant matter within the field of electrical engineering. It's utilized to observe how a device responds when when it receives a abrupt shock. It's like a method to determine if a device can handle abrupt alterations, you know, like how stable it is and how speed of its response. By looking at what comes out of the device after when it receives that shock, we can learn a lot about how its performance.

Like, think about a control device in a factory or someconcept. A positive impulse test can tell engineers how well the device copes with abrupt alterations in what its intended function, making sure it operates efficiently and efficiently. By seeing how its real performance in contrast to our predictions, they can adjust it to improve it.

To do a positive impulse test, you've got to prepare a few things initially. You require the system under test, a signal source, and an oscilloscope. After setting up everything, you give the system a step change input with the signal source and then observe the output on the oscilloscope.

While you're testing, you'll probably want to document the details like rise duration, stabilization time, excess, and final value. Examining these values can tell you performance of the system and assist in identifying any issues. Keep in mind, you've got to maintain a controlled environment thus ensuring reliable results.

It offers many advantages for designers and individuals who develop systems. Firstly, it can quickly identify issues thereby allowing you to correct them before it become significant problems. And second, it gives you a number that indicates the performance of the system is functioning, so that you can evaluate it to other systems or observe how a new configuration is performing.

Moreover? It's non-harmful, so it won't disrupt your system. This indicates that it is an economical and quick method to assess how your system is performing. Therefore, conducting this test, engineers can economize and improve their designs.

Certainly, it is applicable to a wide range of systems, including electrical, and mechanical, as well as control systems. The crucial point is that the system must be capable of accommodating unexpected variations. Irrespective of whether it is a straightforward circuit or a complex control system, the test assists engineers determine the functioning of the system and fine-tune it for improvement.

For instance, in robotics, it can be used to check how a robotic motor or control unit responds to immediate instructions. This info is super important for making sure everything runs smoothly in the physical environment.

This test is cool, but it's good to know how it measures up to other tests to see what it's excelling in and what it's not as strong in. Other tests you might want to look at are the frequency domain test, the temporary response test, and the stability boundary test.

The frequency domain test looks at how the system processes different frequencies and gives you info on its stability and frequency range. The temporary response test is like the positive impulse test but looks at how the system processes abrupt alterations. The stability boundary test tells you how close the system is to becoming unstable.

Every one regarding the tests has its own benefits, and when you use them in combination with the positive impulse test, you obtain a very clear view regarding how the setup is operating.

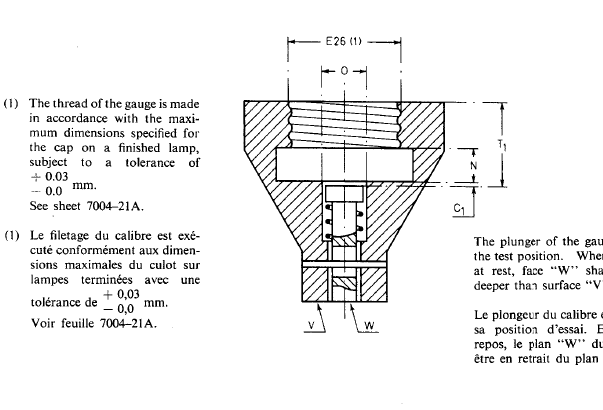

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability