Navigating Thunder Impulse Withstand Voltage Tests

Hey! If you're in the electrical game, you've likely heard of the 'lightning surge test. ' It's a big deal for ensuring equipment reliability and security, especially against lightning strikes. But what's it all in question let's dive into the test and look at the top five things people usually ask.

What's this 'thunder impulse test' all about?

Why is it important for electrical equipment?

How can you improve your equipment's performance in the test?

What are the standards and regulations for these tests?

So, what does this test involve? It's as if the equipment is being struck by lightning. By applying a shock that resembles a lightning bolt, we can determine if it can withstand the strike without failing

Imagine this scenario: a transformer in the power grid system.

Without this test, we are conjecturing about the transformer's ability to endure a lightning strike and maintain power supply to homes and businesses. The test provides us with assurance that the transformer can endure these conditions.

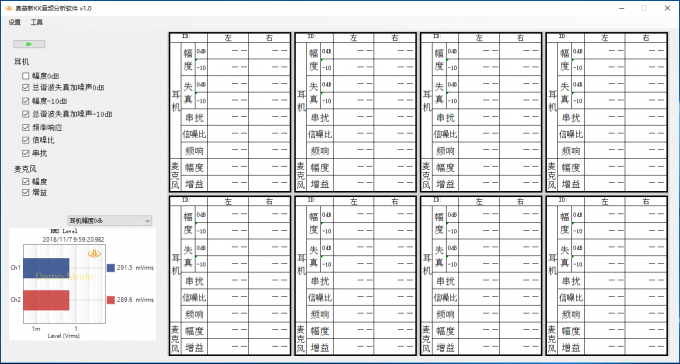

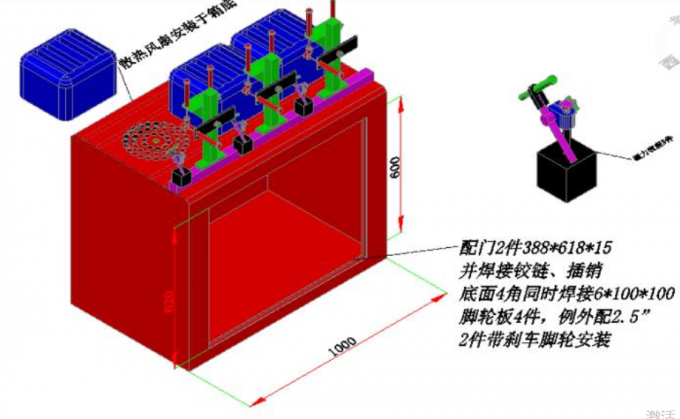

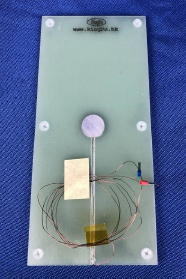

Now that we know the purpose of the test, let's discuss the process of conducting the test They simply discharge the equipment with multiple high-voltage surges using specialized equipment capable of generating the appropriate jolt

They often use a generator to produce high-voltage zaps. The arrangement usually has a surge generator, the device under test, and a transformer to increase the voltage.

These examinations are a big deal for equipment as they ensure it can handle actual operating conditions. Without carrying out these tests, we are only speculating about the capabilities of our equipment.

Consider a scenario where you are constructing a power line in an area prone to frequent lightning. If you don't test your parts, your electrical system may fail during a storm, leaving individuals without electricity. These examinations help prevent such scenarios and guarantee the dependability and safety of your electrical systems.

To make your gear perform the test better, the design is crucial and the materials chosen. Quality components and effective design can significantly improve.

Like, surge protectors and proper grounding ensure the safety of your equipment from lightning strikes. And using durable materials prevent the insulation from from deteriorating under high electrical potential.

There are rules for These assessments to ensure proper execution every time. These standards make sure the results are valuable and are comparable between various equipment and manufacturers.

An important standard is IEC 61000-4-5. It explains how to conduct for protection against lightning. Compliance with these standards is crucial for ensuring your assessment is accurate and your equipment is secure and functions effectively.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview