Why Replace Impulse Lines Before Compression Tests?

During compression testing, you got to exchange the impulse line before the test—it's more than just a technical matter; it's vital for obtaining precise outcomes and ensuring the equipment's safety. So, in this article, we're going to explore the reasons why this is done, discuss certain terms, and include some insights I gained over time within this industry.

Impulse piping are a big deal in a hydraulic testing arrangement. They transfer the fluid from the pump to the thing we're testing, and they've got to be in proper condition for us to achieve precise results.

These hose can get all gunked up over time with including deposit and oxidation, which can disturb the velocity and screw with our pressure measurements, or even damage the machine. So, replacing those lines before we do a pressure test is just a good idea to make sure we get trustworthy results.

Contamination can really mess with a hydraulic system, including our test machines. Minute particles of debris can cause obstructions, decrease the velocity, or at its extreme, totally disturb our equipment. Keeping those lines clean means we maintain system cleanliness and efficient, and we reduce the chances of problems occurring during a test.

As these lines age, they can get tapered and that's a bad thing—they could decrease the fluid, make our measurements worse, and make our hydraulic pump work harder and maybe even overheat. That influences how accurate our test results are, and it can really make the hydraulic pump work too hard, which might even make it overheat. But changing out the lines before a test keeps that pressure drop down, which helps us get better and more trustworthy test results.

Standard Maintenance Practices, like switching out those components prior to testing, enhances equipment longevity and keeps the employee safety. Keeping all equipment in optimal condition helps prevent incidents and property damage to the equipment under test or surrounding area.

Replacing the dynamic lines ahead of our compression testing procedure also makes sure we're conforms to what's expected by the trade safety codes and safety codes. A lot of places demand that testing machinery get scheduled inspections so confidence in the test outcomes. Following protocol ensures reliable test data and it contributes to maintaining our laboratory's standing maintaining a good image.

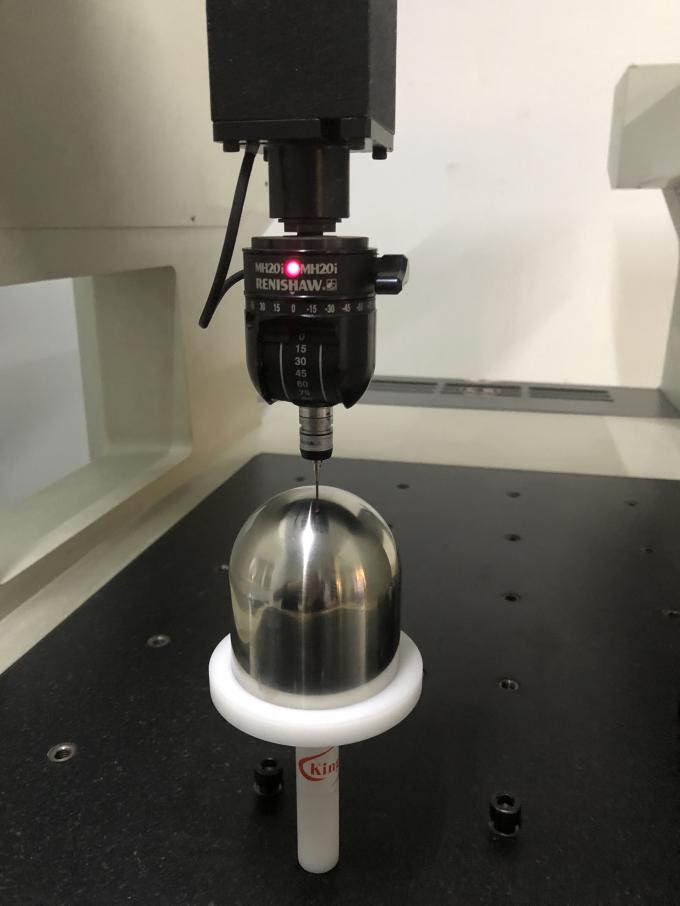

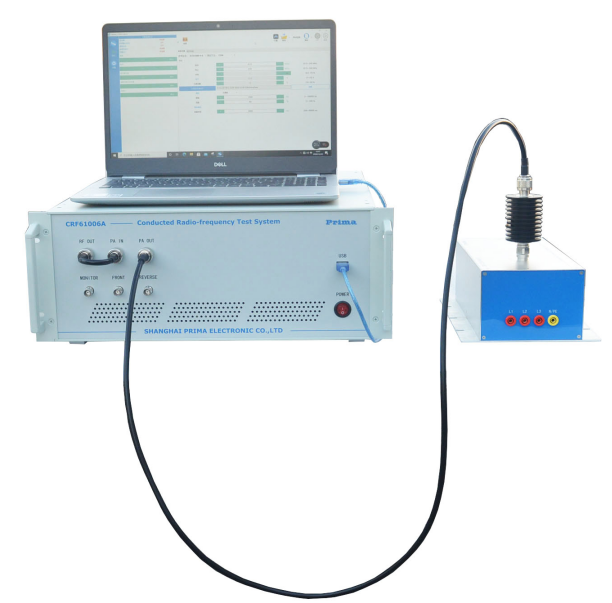

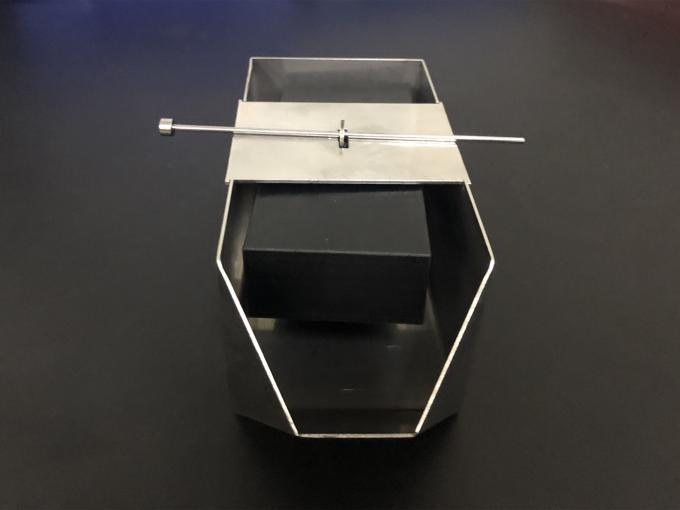

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit