KP-PC-5000A Battery High Current Short Circuit Tester,Battery Tester

KP-PC-5000A Battery High Current Short Circuit Tester,Battery Tester

- Model:

KP-PC-5000A Battery High Current Short Circuit Tester,Battery Tester

High current short circuit tester

Technical Solution

High current short circuit tester.doc

| I. Main technical parameters | ||||||

| Serial number | Project name | Specification parameters | ||||

| 1.01 | Name of equipment | High current short circuit tester | ||||

| 1.02 | Type of equipment | KP-PC-5000A | ||||

| 1.03 | Maximum sustained short circuit current | 5000A | ||||

| 1.04 | Maximum instantaneous short circuit current | 6000A | ||||

| 1.05 | Control system | PC computer remote control system | ||||

| 1.06 | Vacuum Inbox | W 480mm X D 490mm X H 480mm | ||||

| 1.06 | Vacuum range | 10~-101 Kpa( adjustable) | ||||

| 1.07 | DC response time | ≤10 ms | ||||

| 1.08 | Contactor internal resistance | <5 mm | ||||

| 1.09 | Mechanical life | 300,000 | ||||

| 1.10 | Copper wire | (1) Maximum load current :6000 A (2) Length :2 m | ||||

| 1.11 | Test battery | Meet test requirements for modules and battery pack | ||||

| 1.12 | Acquisition system |

Acquisition channel :2 channels Range :0~100 V Acquisition accuracy :±10 mv 5 mv resolution Acquisition frequency :≤100 ms adjustable

Acquisition channel :4 channels Scope :800℃~ normal temperature Acquisition accuracy :±1℃ Resolution :0.5℃ Acquisition frequency :≤100 ms adjustable

Acquisition channel :1 channel Range :0~5000 A Acquisition accuracy :0.5 FS 1 A resolution Acquisition frequency :≤100 ms adjustable | ||||

| 1.13 | Explosion-proof box | (1) Inner Box Size: W 1000*D 1000*H 1000mm (2) Explosion-proof box material: single layer 4 steel plate welding. mm 8 thickness (3) Pressure relief port: the back of the box has a discharge port of 300*300 mm. When the battery explodes, it can release the pressure in time (4) Smoke exhaust system of explosion-proof box: the top is equipped with smoke exhaust fan, the outer diameter of the exhaust pipe is DN102mm | ||||

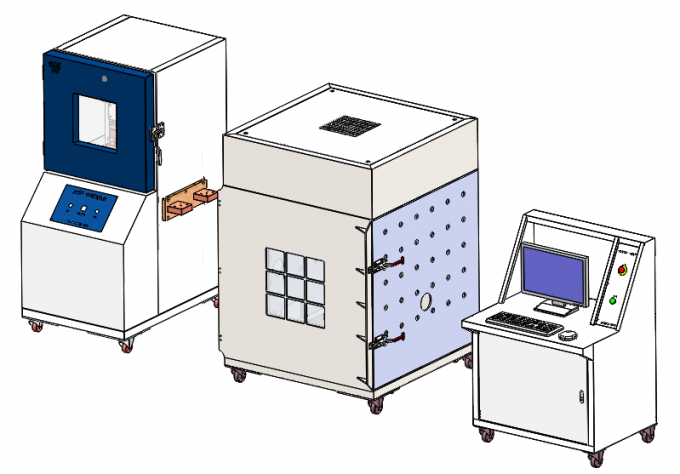

| 1.14 | Overall dimensions | Short circuit host: W 700mm X D1100mm X H1600mm Explosion box: W1020mm X D 1050mm X H1480mm Remote Control Computer Cabinet: W 850mm X D 700mm X H1300mm | ||||

| 1.15 | Weight | about 300 Kg of short circuit main engine Explosion box approximately kg 400 Computer cabinet :50 kg | ||||

| 1.16 | Power supply | AC 220V 50HZ | ||||

| 1.17 | Power | 2KW | ||||

| 1.18 | Use of gas sources | Mpa 0.6 | ||||

| 1.19 | Noise | ≤70 dB | ||||

| II. PRODUCT USE | ||||||

| 2.1 | The remote control high current short circuit device is designed to synthesize various battery short circuit test standard requirements: short circuit in normal temperature environment according to the standard requirements, its short circuit internal resistance range <5 mΩ, simulate external short circuit, and detect the short circuit safety performance of the battery. | |||||

| III. COMPLIANCE OF PRODUCTS | ||||||

| 3.01 | GB/T 31467.3-2015< lithium-ion battery pack and system for electric vehicles-part 3: safety requirements and test methods. GB/T 31485-2015< Safety Requirements and Test Methods of Power Battery for Electric Vehicle Test and Evaluation of Safety Performance of High Power Battery for Automobile under Short Circuit UL1642 lithium battery safety standards | |||||

| IV. Product structure and performance | ||||||

| 4.01 | Remote PC Computer Control System 1: remote control system: the upper computer software is installed in the standard Windows system, the operation is simple and easy to learn, to meet the test requirements. Real-time recording of current; voltage; temperature, time, observation and analysis simple and convenient.The control distance ≥10 m. | |||||

| 4.02 | Structure Description 1: short circuit mainframe Double safety pneumatic copper contactor short circuit mode :1 normally open contactor, the other 1 is normally closed contactor. The double-axis high-precision cylinder with short-circuit opening contactor will close the copper connecting block of positive and negative electrode to form a circuit to achieve short-circuit purpose. When the short-circuit time is reached, the contactor will open normally, and the contactor will also open normally. The purpose is to prevent the normally open contactor from accidentally sintering, and the normally closed contactor can open in time, so as to avoid the safety accident caused by the battery short-circuit test because the contactor can not break. Vacuum arc extinguishing mode: the double safety contactor is installed in the vacuum box, the vacuum pumping makes the air in the box thin, the contact surface of the contactor will not produce arc when short circuit, so that the contact surface will not be sintered, and the service life will be prolonged to reduce the failure rate. Vacuum control system: through vacuum pump, vacuum valve, pressure sensor, high pressure gas pipe, joint and other vacuum connectors to the box internal pressure control. | |||||

| 4.03 | Security protection function (1) Emergency stop protection function: The equipment and the computer control cabinet are each equipped with an emergency stop switch.When an emergency occurs or you want to stop the test, you can press this switch to stop the output of the control board and stop all test actions. (2)Three-color lights sound and light alarm system: The equipment is equipped with a three-color alarm lamp, the light flashing alarm reminds the personnel equipment different test status. (3) Fault display (4) Power-off protection function (5) Electrical safety protection; (6) Leakage protection, overheating protection; | |||||

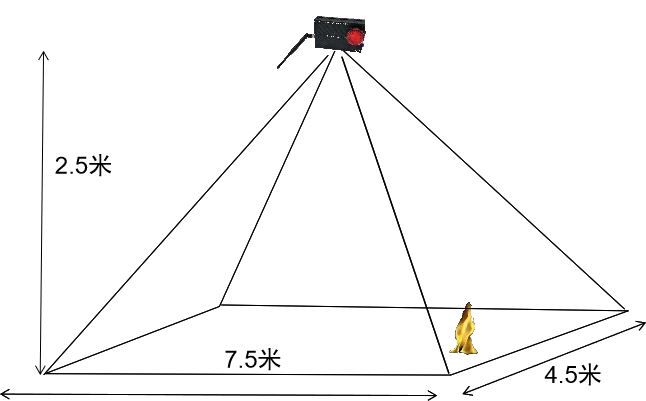

| 4.04 | Equipment installation conditions: 1. installation in place: the equipment can be unloaded through a 2 ton forklift, after moving into the laboratory, adjust the distance between the rear part of the equipment and the left and right sides of the wall ≥1000 mm, the front operation space ≥1500 to facilitate the operation test, after fixing the equipment. Power cord and compressed gas source: air source pressure ≥0.6 Mpa 2. ground bearing ≥500 kg/㎡. 3. Laboratory: The entire laboratory must have a ventilation system to discharge the smoke leaked during the test; the lighting is good, and it is convenient to watch the operating equipment. 4. The passage of the laboratory should be convenient to transport batteries and related transportation vehicles. People can be evacuated in time when a special emergency situation occurs. 5. laboratory should be equipped with corresponding fire fighting facilities to facilitate the use of its fire fighting tools. 6. ambient temperature: room temperature -35℃ 7. Environmental Humidity :85% R.H ≤ | |||||

| V. Standard configuration | ||||||

| Configuration Name | Quantity | Configuration Name | Quantity | |||

| Short circuit mainframe | 1 unit | Operating instructions | 1. | |||

| Explosion-proof box | 1 unit | Collection line | Article 10 | |||

| Remote computer control cabinet | 1 unit | Data acquisition system | 1 set | |||

| Conductor-2m | Article 2 | |||||

| VI. List of equipment accessories | ||||||

| Name of accessories | Origin/brand | Name of accessories | Origin/brand | |||

| Computer Control System | Yiqiao Tai'an, Guangdong | Computer mainframe | China, Lenovo | |||

| Lead wire | Yiqiao Tai'an, Guangdong | Data acquisition system | KINGPO | |||

| Current sensor | Hall sensor, Nanjing | Intermediate relay 2 P 24V | Schneider, France | |||

| Cylinder | SNS, Taiwan | Ac contactor CU-11 | Taiwan, Taiwan | |||

| Pneumatic solenoid valve | SNS, Taiwan | Button ∮22 220V | Hongbo, China | |||

| Gas source filter | SNS, Taiwan | Vacuum baffle valve | Simat, Shanghai | |||

Design reference drawing