Temperature-type Battery Short Circuit Tester , IEC62133 Battery Short Circuit Tester

Temperature-type Battery Short Circuit Tester , IEC62133 Battery Short Circuit Tester

- Model:

Temperature-type Battery Short Circuit Tester , IEC62133 Battery Short Circuit Tester

Temperature-type Battery Short Circuit Tester , IEC62133 Battery Short Circuit Tester

Standard

It is conforms to IEC62133 clause 7.3.2 ,8.3.1,8.3.2 IEC60086-4 clause 6.5.1 IEC60086-4 clause 6.5.8 6.5.9 ,IEC 60086-1 ,IEC61951,IEC61960, UN38.3 ,UL1642, UL2054, QC 743/744, MT/T 1051-2007,GB/T 2900.11-1988,GB31241-2014and etc.

Feature:

| High current contactor | (1)remotely connect and disconnect DC operational voltage to 220V; (2)rated operational current 1000A;equipped with series clay magnetic blowout cover and system (3)electromagnetic system and main contact arc-extinguishing system are fixed on bottom; main contact is made of red copper;low contact resistance,rapid reaction speed; (4)Reliable and safe;long service life and convenient maintenance; |

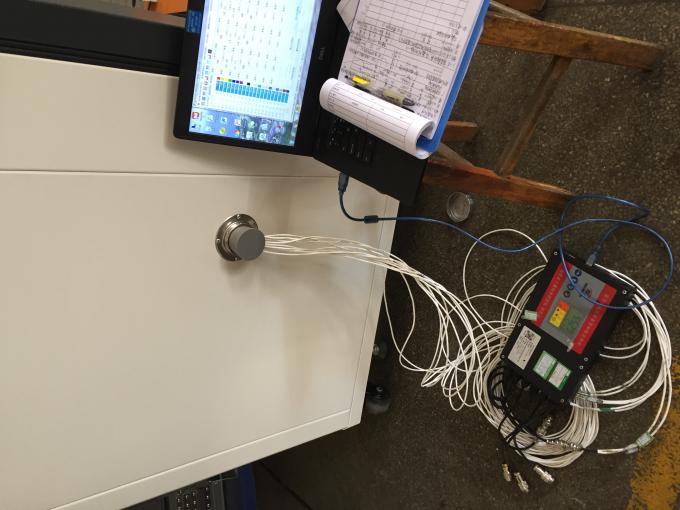

| Remote controller | (1)long distance wireless control; (2)reliable and stable;auto lock and interlock; anti-interference and long service life; |

| Voltmeter | (1)measurement voltage:0-100V; (2)display accuracy:F.S ±0.2% rdg ±1digit; (3)motion:double integral |

| Ammeter | (1)measurement current:0-1000A DC one level; (2)display accuracy:F.S±0.2% rdg±1digit; (3)motion:double integral |

| Basic Configuration | Consist of high current contactor,remote controller,voltmeter,ammeter,etc (2)accessories,special tool,spare parts,etc |

| Touch screen interface(English) |

|

| USB Interface | export data via USB |

| Technical Parameter: | |

| 1 max short circuit current | 1000A |

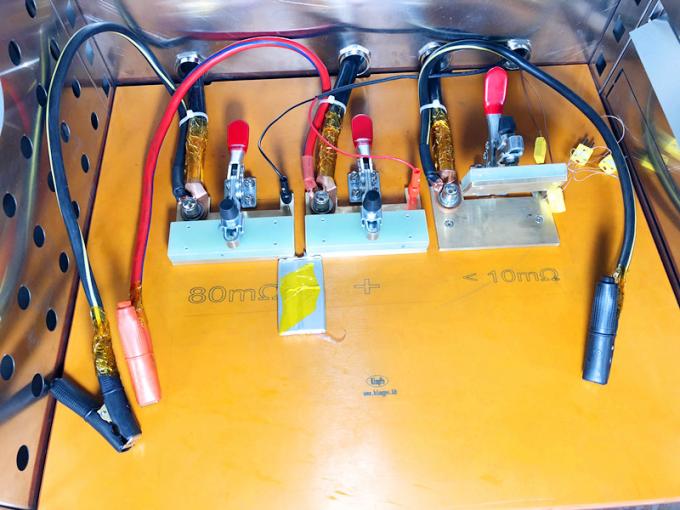

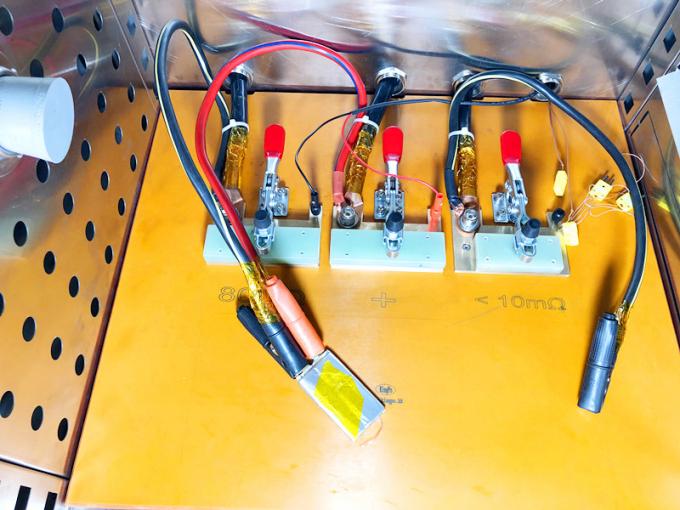

| 2 resistance | 80±20 mΩ |

| 3 Control Distance | no solid barrier7m |

| 4 mechanical life | 300,000 times |

| 5 Electrical life | Resistive load 50,000 times |

| 6Temperature Range | room temperature +10℃~ 80℃(meet test condition of 55℃±5℃ and 25℃±5℃) |

| 7 Temperature fluctuation | ±1℃ |

| 8 Temperature deviation | ±2℃ |

| 9 Internal dimension | W600 X D500 X H600mm |

| 10 Internal material | 304# stainless steel(thickness 1.0mm) |

| 11 External dimension | W940XD780XH1620 mm |

| 12 External material | cold rolled plate baking varnish(thickness 1.0mm,total thickness of internal chamber 100mm) |

| 13 Observation window | 390 X 360mm(20mm thick toughened explosion-proof glass) |

| 14 Light design | highlighted energy-saving lamp |

| 15 test hole | 3 holes(diameter :φ50mm) ;3 stainless steel covers;3 silicone plugs |

| 16 pulley | easy to move with strengthening screw bolt |

| 17 heating system | Fin Type Heat Dissipation tube nickel-chrome U-type high efficiency heater |

| 18 circulation system | stainless steel lengthened axis ;moisture proof and Heat Dissipation sirocco fan; |

| 19 air-deflector | Can adjust up and down,left and right;to ensure uniform distribution of temperature |

| 20 Exhaust System | On the back of equipment;can make waste gas exhaust through it |

| 21 Power supply; | AC220V 50HZ |

| 22 Power | 3.0KW |

Operation room

Installation

1.Operation condition requirement: temperature-10℃~100℃ humidity 10~90% with no condensation

2.Other:locate the machine on a plane table with certain intensity.

3.Test requirement:

(1)install a battery in explosion proof box(standard)

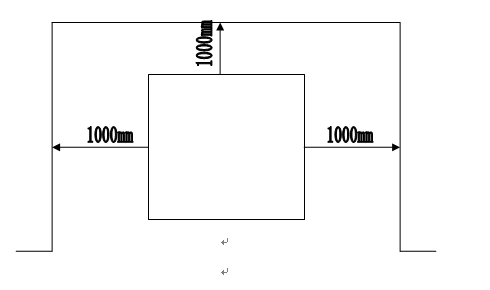

(2)Independent cement room,has observation window for monitoring and controlling (customer self-prepare)

4.Power:AC 1φ 3W 220V

5.Installation site(suggestion):