Top 5 Demands for Surgical Instruments

In the rapid healthcare industry, medical instruments are super important. Thanks to all the cool new medical gadgets, we're seeing a big requirement for clever and effective surgical equipment. This article talks about the leading five highly favored surgical tool developments, and why they're extremely significant.

2. Minimally Invasive Procedures

5. Eco-Friendly Surgical Instruments

One of the highest priority needs in the surgical instruments industry is for improved sterilization methods. The Centers for Disease Control and Prevention reports about one out of every 20 people contract an infection when they're within the healthcare facility.

Advanced sanitation techniques reduce the incidence of infections and increase patients' sense of safety and happiness. Like, steam sanitization is really popular because it eliminates many harmful microorganisms.

Lately, non-invasive surgery is the way to go, accelerating patient recovery and with reduced pain. This popularity has led to all sorts of innovative surgical instruments for those less-invasive surgeries.

For example, laparoscopic devices let surgeons perform their tasks with small incisions. The Journal of the American College of Surgeons says these less-invasive procedures mean reduced hospitalization periods and lower healthcare costs.

Robots have totally transformed the field in surgery. Robotic tools are extremely accurate and enable surgeons to perform complex tasks with greater precision.

The American Society of Mechanical Engineers says the market for robotic surgery systems is gonna be worth approximately $30 billion in the year 2025. Numerous robotic systems are available out there, such as the da Vinci system, which is applied for procedures involving the prostate and gynecological surgeries.

People are really into custom surgical tools because each patient's needs are diverse. Bespoke surgical instruments enable surgeons to adjust their devices to fit each patient's body, which could potentially result in improved outcomes.

These are typically produced bespoke surgical instruments using 3D printing, that boasts remarkable accuracy. The Journal for Biomedical Materials conducted a study demonstrating that how bespoke surgical instruments can help patients achieve improved results and mitigate the likelihood of complications.

High-quality stainless steel is a hit because it has a long-lasting duration and is recyclable. The World Health Organization (WHO) says utilizing environmentally friendly surgical instruments can reduce medical waste and make health facilities more environmentally conscious.

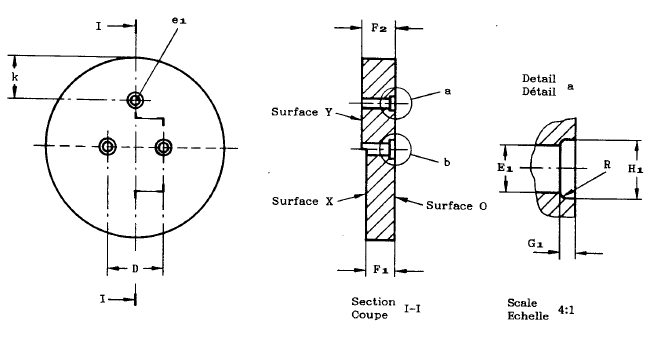

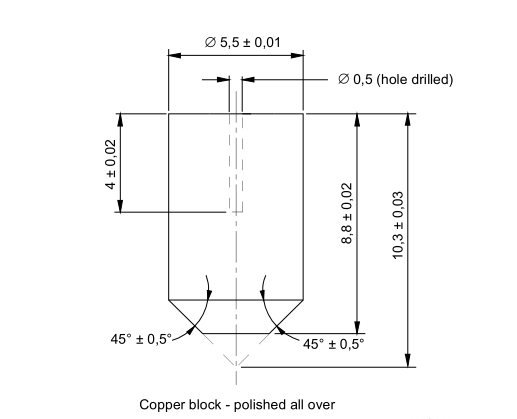

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

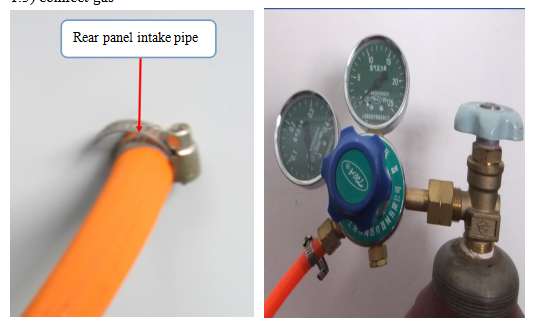

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment