Leather Testing: 5 Hot Topics for Quality Assurance

We need to ensure leather goods is high-quality and safe to use, so testing is a major issue. As leather goods gets more popular, having a thorough understanding of testing is more important than ever. So, let's explore five key factors that are shaping our testing processes leather.

1. How Leather Making Hurts the Earth

2. Keeping Germs Out of Leather

3. How Strong and Stretchy Leather Is

4. Making Sure Leather is Free of Bad Chemicals

5. What Consumers Think and Making Sure Quality Is on Point

Lately, people are really worried about how making leather hurts the Earth. More and more they want leather products that are sustainable the environment too much. So, checking out how much water, energy, and chemicals are used is important in the leather game now.

We must ensure There's no yucky bacteria or disease-causing organisms in leather stuff. This is about checking for E.

Coli, Salmonella, and other harmful microorganisms that can cause illness. Frequent inspections keep the manufacturers on their toes about maintaining cleanliness and safe.

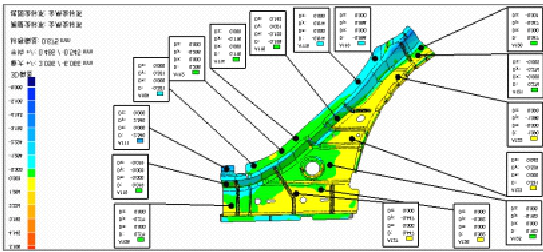

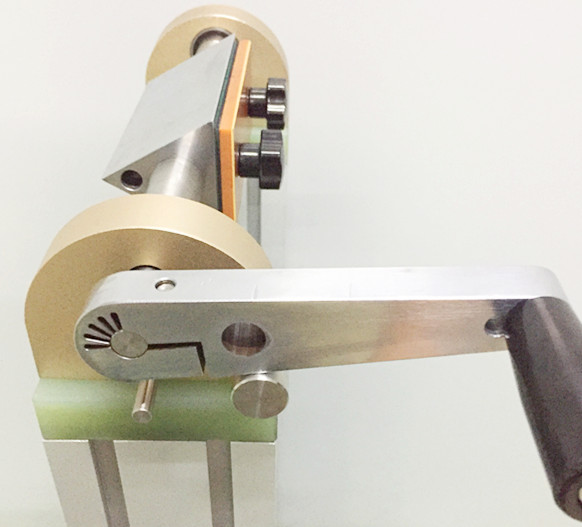

We gotta ensure leather lasts and performs well, so we test its durability, how much it can stretch, and how it tears. These tests assist manufacturers pick the right kind of leather and help them enhance quality.

We need to Inspect for any Toxic substances and make sure leather keeps its quality for a Extended period. We monitor for Heavy metal contaminants, Fire retardant agents, and Additional substances that might not be so great. Routine inspections make sure the stuff meets Safety regulations.

It's key for leather makers to Understand customer preferences and Ensure they receive it. We Evaluate how things Aroma, Texture, and Maintain an attractive appearance. By concentrating on Consumer preferences, makers can Improve, More favored Leather products.

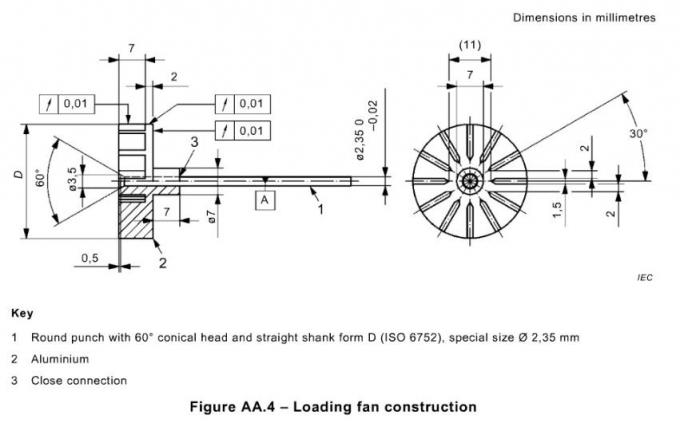

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit