Grasping Leather Thickness: Methods and Insights

Have you ever considered about how they determine what the depth of the leather's depth? It's an issue that is commonly inquired about in the leather industry, and it's extremely crucial to ensure correctness. Irrespective of whether you are a leather craftsman, a customer, or simply interested, understanding how they determine the leather's depth can enable you to make informed decisions.

So, what are the usual ways they measure leather thickness?

So how do you actually measure leather thickness by hand?

Can anything mess up how thick they say the leather is?

So how do you make sure you're getting the same thickness every time?

There are various techniques for calculating leather dimension, each having its unique benefits and limitations. The usual tools are this caliper tool, this micrometer instrument, and this thing called a dimension measure tool.

This caliper tool is a portable device that offers swift and precise measurement, while this micrometer instrument offers even more precise accuracy. Then there's the dimension gauging device tool, which is somewhat more sophisticated. It can assess material in various locations and is often employed in large factories.

You require a caliper or a micrometer to assess material dimension manually. Using a caliper, just place the material between the two sections and compress them towards each other until they contact the material.

The value on the instrument shows you its gauge. With a device, you require to initialize to zero first, then place the leather in the gaps and turn the screw until it touches the leather. The value on the device shows you the gauge.

Yeah, there are a few things that can mess with the precision of the gauge. It's factors like how good the device is, how you take a measurement, and type of leather it is.

Like if the instrument or device isn't set up right, it can produce the wrong value. And if the leather isn't even or you're not doing it the same way consistently, it can be wrong.

To ensure the dimensions are consistent, you need to do a few things. Initially, ensure your equipment are all prepare right and in in good condition.

Secondly, constantly do it the identical manner every time you take dimensions of the leather. That implies putting the leather in the consistent location and pressing evenly every time. And Finally, record your dimensions so you can check for any issues.

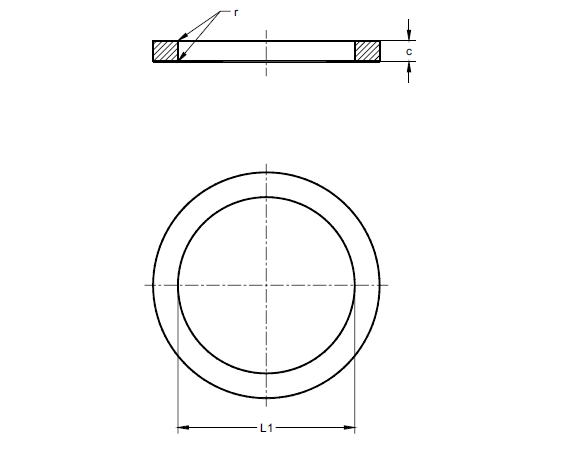

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit