Purchase Transformer Safety: The Power of Impulse Tests

Hey, transformers lovers! Ever think about why these fast assessments are such a big deal in The unit realm? Well, fasten in, we're delving deeply into why these tests are a big deal for transformers. We're going to hit on five primary points here and talk them through, no holds barred. Alright, let's plunge in!

First off, keeping the transformer solid.

Next, making the transformer trustworthy.

Then, keeping the transformer from breaking down.

Next up, boosting the transformer's performance.

Last but not least, meeting the standards.

Quick tests are a must for maintaining transformers intact. These tests detect any deceptiveness in the transformer coils, electric insulation, and that core materials. Early detection of issues is a substantial advantage, it cost savings on rectifications and keeps the transformer operational. It's like performing a quick health check on the transformer to make sure everything is in order and zipping along.

Reliability must be ensured with transformers, and These tests play a significant role in assisting us get there. They evaluate the transformer's ability to withstand high-voltage surges without failing. It's as if we're giving the transformer a rigorous test to see if it can handle the stress. Believe me, you need a transformer tough enough to withstand the stress!

When fail, it's a stress, for sure, both financially and in the maintenance team. Diagnostic tests help identify possible weaknesses in transformers, allowing you to take preventive actions and avoid unplanned outage. It's like having a prediction tool to know what's coming, so you can avoid problems in the future. Come on, who wouldn't want that?

These tests detect issues but also help the transformer perform optimally. After resolving these subtle problems, the transformer gets to work at maximum efficiency. It's as if you're giving the transformer a motivate to make it do even better. That's maximizing your investment, for sure!

Those exams ensure the converter complies with all the regulations and safety measures. They verify that your converter meets all the security and operational requirements. It is similar to receiving a thumbs-up from the experts, indicating that your converter is in excellent condition.

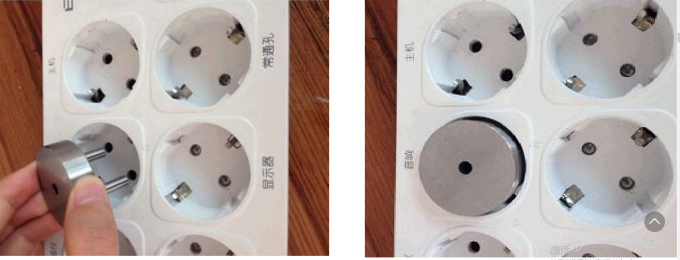

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability