Decoding Impulse Testing in Hydraulics: How It's Done

You got to do this label Impulse Examination on hydraulic circuits. It's fundamental for sure this components maintain integrity and perform correctly. So what they do is inflating instantly observe how it deal withs the pressure and spots potential weaknesses. We're going to delve into five main components Impulse Examination thing, and we'll tell you what its significance is and how they implement the process.

What is Impulse Testing Hydraulic?

Why is Impulse Testing Necessary?

How is Impulse Testing Conducted?

Benefits of Impulse Testing Hydraulic Systems

Hydraulic impulse testing is a non-destructive inspection method used to assess the capacity of hydraulic systems to withstand abrupt pressure variations. It's a practical approach that simulates real-life conditions, helping engineers and technicians to identify potential breakdowns before they occur.

You just with water, then increase the pressure rapidly fast. They observe how the system reacts to ensure it's still fit for use.

We need it to avoid major failures in the systems. It detects leaks or fractures before the system goes kaput, saving effort and money. For example, in the aviation industry, where hydraulic systems are crucial for aircraft control, impulse testing is a routine practice to ensure system dependability.

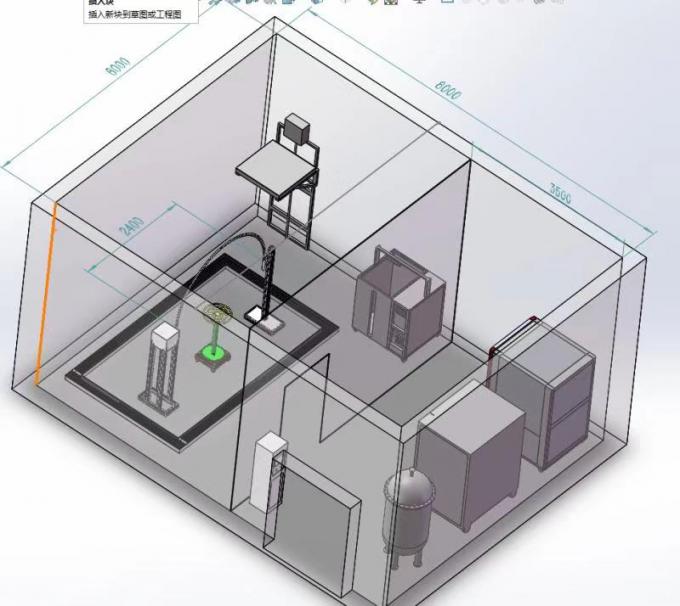

They perform it in a controlled environment so as not to damage anything else during the testing process. Begin by filling it with water, and then connect it to this pump to increase the pressure.

They have sensors to monitor the pressure and observe how the system behaves. If it fails to withstand, they release the pressure and inspect for any damage.

One significant advantage of this testing method is that it's reasonably affordable. Discovering and resolving issues promptly results in a reduced likelihood of costly repairs or the system failing.

And it enhances safety by ensuring the systems are dependable and functioning correctly. Consider construction equipment, for instance, which relies on hydraulics to lift heavy loads. Impulse testing is crucial for ensuring the safety of the workers.

Even though it's an effective tool, it has its difficulties. The major challenge is ensuring the test seems like actual conditions.

And the additional challenge is interpreting the results correctly to detect any issues. Engineers need to know much knowledge of hydraulics to ensure they are evaluating it accurately.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO 2024 R&D Results Report

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability