Foam's Resilience: A Deep Dive

When we're talking about material, you really can't ignore how essential material rebound resilience is. That's when firms that evaluate material rebound resilience jump in, giving us answers to make sure our material is excellent. These guys are a major deal because they evaluate and validate material products, making sure this's robust and will endure.

What is Foam Rebound Resilience Testing?

Why is it Important for Foam Manufacturers?

How does a Foam Rebound Resilience Tester Work?

Real-world Applications of Foam Rebound Resilience Testing

Material recover shape test is a way to verify if material can recover shape to its original shape after it gets squished. It's crucial to determine how good material is for making items such as sofa cushions, shipping materials, or automotive seating. They measure how far a material sample can recover shape to how it was before, that informs us how strong it is.

Material makers really need to understand their material's resilience, it's extremely crucial. It ensures their material is up to snuff, both what the customer satisfaction and complies with industry regulations.

Using a material rebound tester assists manufacturers in adjusting their material recipe for improved quality and increased customer satisfaction. It also reduces product returns and enhances brand reputation.

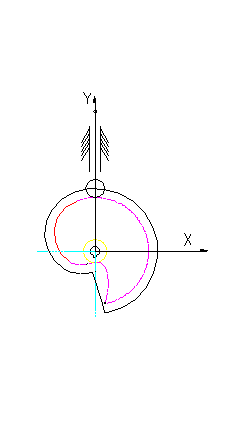

A foam resilience tester is a fancy machine that puts force on a foam specimen, compressing it down a bit. The tester waits for a bit and then checks how far the foam rebounds after it's been squeezed. Then they use this info to figure out the foam's 'rebound' rating, which tells us how good the product is.

Imagine a furniture designer who wants to make the best couch cushion. The foam tester helps them pick the suitable type of foam for comfort and to make sure it lasts. And the same goes for vehicle seats – the testing makes sure they stay comfortable over the time.

We had a customer who makes sporting foam and they told us about their experience with our tester. They stated, 'The tester has been crucial in enhancing our quality of product.

It lets us continue producing foam that's up to our rigorous standards and those of our clientele. ' These examples show how important foam assessment is for producing exceptional items.

According to a report by MarketsandMarkets, the global foam assessment equipment market is expected to grow to a estimated to be worth $540 million by the year the year 2025. This this surge indicates just how considerable importance foam assessment is getting in a variety of sectors.

So, in the end, companies that do foam assessment are at the forefront ensuring the foam meets the required quality. They're extremely crucial in facilitating the procedure and they make a significant impact on consumer perception of the item.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability