Maximizing Safety with Impact Tester Falling Weight: A Real-World Insight

So, when we're talking about ensuring construction materials are safe and of high quality, this thing called impact tester falling weight is super important. This cool gadget assesses how well materials can withstand an impact, and it's a important factor in ensuring that the materials meet the required standards. Alright, let's jump into this impact tester falling weight stuff and see how big of a deal it is in various industries.

3. Calibration and Maintenance

5. Application in Different Industries

Resilience is just how much energy a material can absorb when it gets smacked. When dealing with this impact test device, we need to see how a material handles when it gets hit all of a sudden. According to some study by ASTM, materials that can take a good hit usually perform well in the real world, like in cars and buildings.

We've actually seen that stuff like high-performance steel and some plastics can handle a good hit when this falling weight test is done. Like, in the automotive industry, they crash cars into things to make sure they're safe. This impact test device does a good job of making these crashes in a controlled way so they can fine-tune materials and designs.

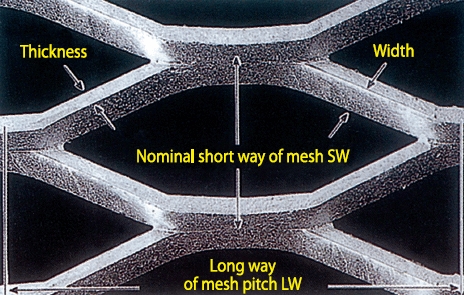

The height and weight of the thing that falls in this tester are extremely important for getting good test outcomes. How high the weight drops replicates the energy of a genuine impact, and the mass in question determines how hard it hits the material. According to NIST, you gotta pick the appropriate height and mass for the material and intended application.

For instance, if you're evaluating glass for windows, you want to throw something light, like a stone, to see how it holds up. But if you're testing automotive steel components, you need to throw something heavier, like another vehicle, to see how it handles the hit.

We've found that picking just the right height of the drop and mass is key to getting trustworthy testing outcomes. This way, you make sure the materials being used are secure and efficient.

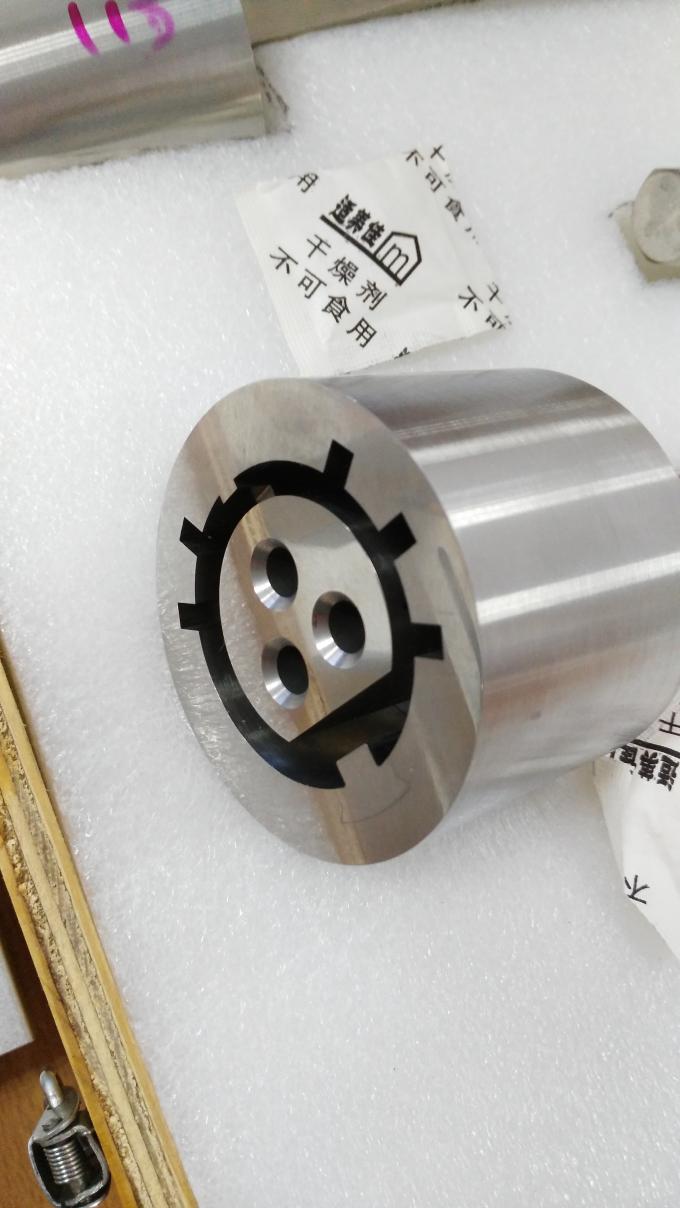

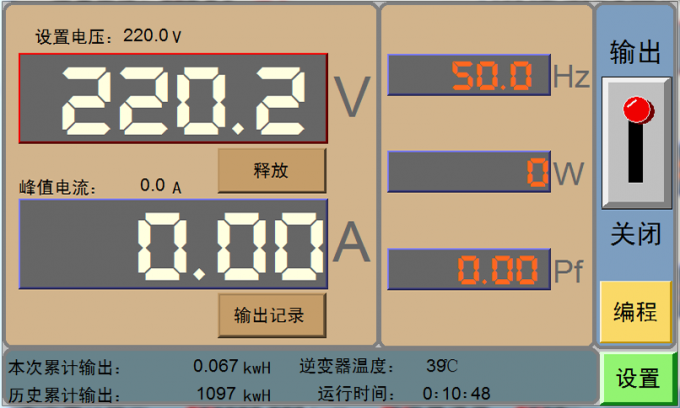

Keeping this tester in optimal condition with regular frequent calibration and upkeep is super important for getting accurate tests. Frequent calibration keeps the tester accurately calibrated, and good upkeep makes sure it lasts a long time and functions correctly. Some studies indicate that performing calibration on these testers more often means you get better results, which helps with choosing the right components and constructions.

At our facility, we've got a rigid schedule for managing this device calibrated and serviced. This not only makes sure our test outcomes are perfectly accurate but also gives our clients reliable information they can count on. We have found that regular calibration and maintenance also add to the complete efficiency of our assessment process.

There are regulations and standards for operating this device in different industries. These directions make sure the test outcomes are the same no matter where they be completed. According to this European Norm, you've got to adhere to specific procedures to make sure this tool gives you precise and dependable outcomes.

For instance, in construction, this tool is used to see how strong concrete's strength. Following the EN 12667 regulations makes sure the test outcomes can be trusted and can assist us assess how good the concrete's strength in real-life situations.

The testing device is used in a multitude of sectors. It's used in automobiles, structures, aircraft, sporting equipment, and more, to ensure that products are secure and functional. The American Concrete Institute says The testing device is extremely crucial for evaluating the strength of concrete, which is a significant matter in construction industry.

At our testing center, we have witnessed the impact tester falling weight being used to evaluate materials across a wide range of uses, including:

- Automotive parts

- construction industry materials, such as concrete and steel structures

- Aerospace applications, such as aviation components

- Athletic equipment, such as golf clubs and skiing equipment

Using The testing device, we have managed to assist our customers ensure their products comply with all safety and performance requirements.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment