Upgrade Your Testing with Advanced Bending Resistance

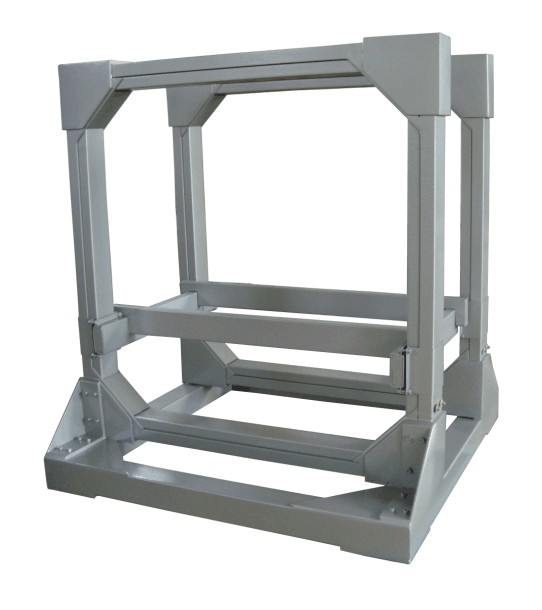

Hi, as a material tester, I've recognized that a bending resistance tester is a super critical device for evaluating how strong Substances are. And through the period, I've observed a several aspects that all appears to is searching for in bending resistance testers.

1. Accurate Measurement of Bending Resistance

2. Versatility in Testing Different Materials

3. User-Friendly Interface and Easy Operation

4. Data Analysis and Reporting Capabilities

Precision in assessing bending resistance is top on the list for most people. I mean, as a materials scientist, I know that super accurate measurements can have a significant impact when it's time to make decisions.

For example, on a recent project, we used this bending tester to figure out how strong a new type of material is. And the results were exactly on target, which was great for deciding how this new material might be used.

And another thing people really want is a tester that can accommodate a wide variety of materials. In my book, that adaptability is key for getting reliable and dependable outcomes.

Like, my team and I have tested everything from plastics to metals with our advanced bending testing device. And that's helped us give a complete overview of how different materials handle bending, super useful for making products and checking quality.

Something important to think about when picking out a bending machine is how easy it is to use. And since I train newcomers pretty often, I like when the tester has a simplified design and doesn't require extensive explanation.

Just recently, I managed to get a newcomer using our tester in thirty minutes. This makes things way quicker and makes sure everyone on the group can help with the testing.

And a important aspect people look for is a tester that can manage analysis data and reporting results seamlessly. In my industry, I've noticed that being able to analyze the data and promptly disseminate them is a key element in keeping up with the competition. Our tester makes it super easy to make detailed documents with a a few clicks, which has really boosted our performance.

Finally, reducing expenses is a significant matter for a lot of my customers. I mean, I've seen that getting a high-quality bend tester can really be very useful over time. Like, for example, by getting a tester that's exactly right and adaptable, we've reduce the quantity of testing we need to do, saving both effort and materials.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit