Plug Bending Tester: The Ultimate Guide to Quality Assurance

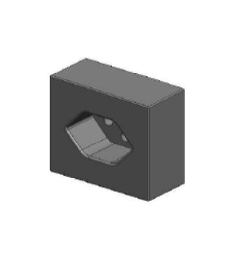

Manufacturing sector continues to grow, and it is crucial to make sure parts are of high quality and reliable. We've got this awesome tool called a plug bending tester. It's designed to test how tough parts with a plug shape are. This tester is used a lot in different fields. Let us discuss the five key features that people desire in one.

Number one, we need it to measure how much force we're applying really well.

2. High Precision and Consistency

And number three, it's gotta be super easy to use, like, no-brainer kind of thing.

Number four, it should be able to test all sorts of different stuff, from metal to plastic.

And last but not least, number five, it's gotta be tough and last a long time.

The main job of this tester is to measure how much force we're using to bend the plug. This is crucial to make sure the plug is adequate and can manage any its intended function. We've heard from users who said our tester helped them identify a design defect that could have could have led to parts breaking.

People really want the tester to measure stuff super accurately and keep being reliable. This is super important so the testing outcomes are dependable for making sure stuff is good quality. Our team has made these testers that are renowned for being extraordinarily precise and stable. They have numerous accolades as evidence

Companies seek testers that are user-friendly and don't take forever to train on. Our testers are designed such that anyone can operate them, no specialized knowledge necessary. Users have informed us they appreciate the simplicity and efficiency of our testers are.

These testers have to be able to handle various materials, like metals and polymers. Our testers are configured for usage with different materials and can be quickly adapted for various tasks. We had a client who informed us how our tester helped them inspect components of various materials, which made their manufacturing improved.

As factories can be sturdy on machinery, these devices need to be robust or trustworthy. Our products are produced using high-quality materials or rigorously tested in order to ensure they can horle the everyday workload. Our clients appreciate the fact that long these devices last or how reliable they are.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability