Advanced Accelerated Weathering Tester: Unveiling the Secrets

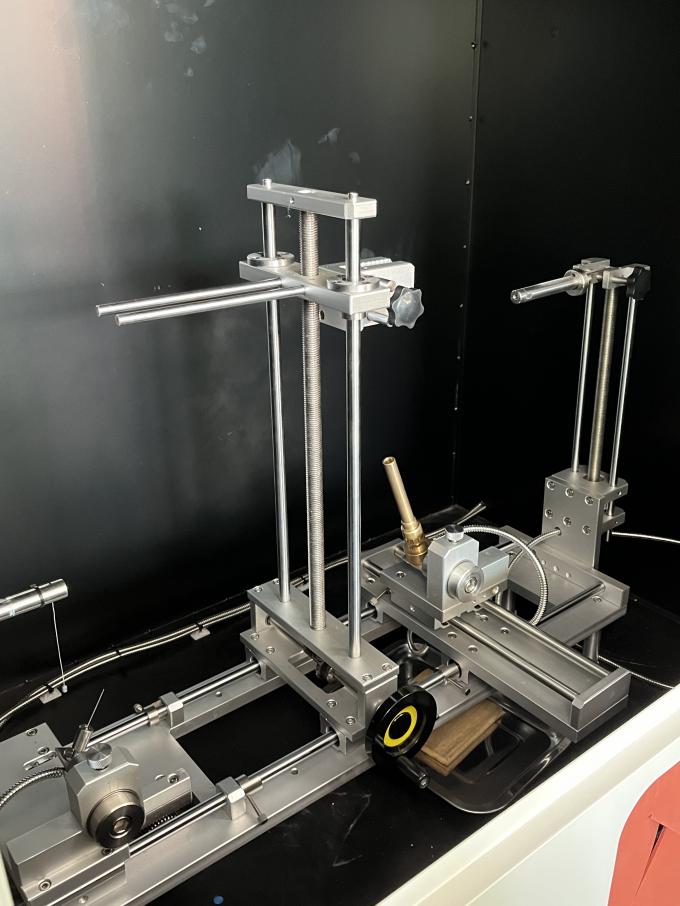

When it's time to figure out how strong stuff is, an accelerated weathering tester can be a total lifesaver. It's like a highly advanced apparatus that makes tough weather act nice temporarily so we can determine the material durability longitudinally. Alright, let's explore five super key aspects of the impressive tester which we are discussing.

1. The Science Behind Accelerated Weathering

2. Applications in Various Industries

3. The Importance of Calibration and Maintenance

4. The Role of Software in Accelerated Weathering

5. The Future of Accelerated Weathering Testing

Now, understanding the mechanism behind this quick weathering process is very important, especially if you're operating one of these devices. So, they subject materials to severe conditions—high temperatures, ultraviolet radiation, and humidity— just like they'd be subjected over a period of several years, all compressed into a few days. That allows us to identify any weaknesses in the materials quick and improves their resistance to environmental factors.

They're extremely helpful for all sorts of things, like examining car paints or house roofs. They're utilized in facilities such as car manufacturing plants for maintaining the freshness of car paints and plastics, or construction sites to evaluate the durability of roofing materials,。 And they're critical in spacecraft and similar applications where materials must be extremely robust.

You gotta achieve accurate and reliable outcomes with an accelerated weathering test. You gotta ensure the device is properly set up and maintain it if you want to get reliable results.

This process involves checking the device's sensors, ensuring proper temperature control, and verifying the accuracy of the timer. Omitting calibration and maintenance can ruin your results big time, and This is not good news for the test items.

These days, these testing devices have got some pretty cool software that lets you monitor and observe the results in real-time. The software can trace the test throughout its duration, provide you with comprehensive information, and even inform you of how long a material is expected to endure under various weather conditions. With this tech, studysts and engineers can make informed decisions about what materials to select and how to develop their design.

The future prospect for rapid weathering tests appears promising, with all these technological advancements and novel methods impending. There's also new stuff coming like nano-composites and self-repairing materials to help materials be more resilient under extreme weather conditions. And we're also going to see some substantial advancements with artificial intelligence and machine learning enhancing the precision and speed of these tests.

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability