Purchase Insights: Pharma Packaging Testing Demands

You know, examining the packaging of medications is really critical to ensuring their safety and effectiveness. With more and more individuals requiring medication, we need highly robust testing for packaging to ensure it meets the necessary standards. We're gonna talk about the top five things people ask for when testing drug packaging and give you a peek at how we handle them at our place.

1. Material Compatibility Testing

2. Barrier Performance Testing

5. Labeling and Serialization Testing

A major factor we examine is if the packaging materials are compatible with the medication. We conduct tests to determine if the materials interact with the drug, ensuring they do not compromise the medication's quality.

We have a multitude of tests in our laboratory to determine if the materials are suitable, such as examining what potential emissions they may produce or how they behave. We have discovered that communicating with our clients greatly assists us grasp their requirements and ensure our tests are appropriately tailored to them.

Many individuals aim to ensure the packaging maintains the medication's safety from factors such as light, humidity, and air. Our team has extensive experience performing tests on the packaging to assess how effectively it excludes light, humidity, and air using state-of-the-art equipment. We have learned that utilizing a variety of testing techniques and possessing practical experience assists us achieve precise outcomes.

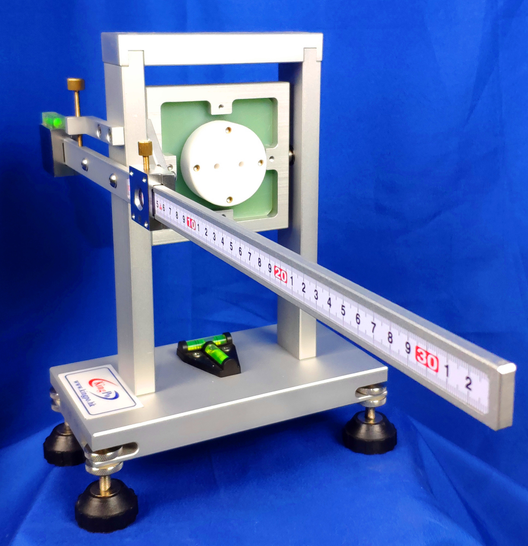

We need to make sure the packaging can handle regular use and shipping without damage. We conduct tests by dropping objects on the packaging and shaking it up to see if it's strong enough. We've seen that keeping our testing methods and gear up to date is key to keeping up with new Packaging Technology.

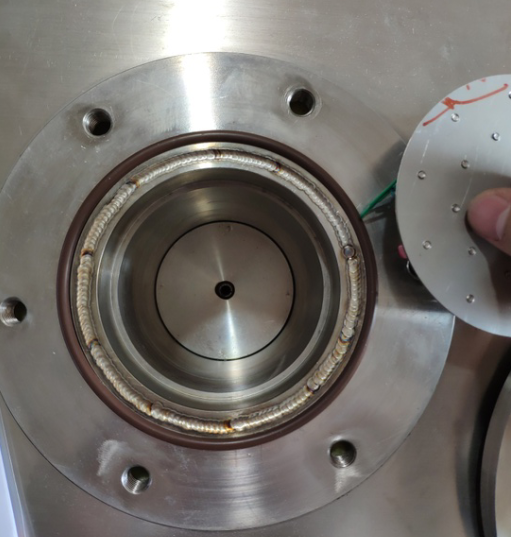

We've got to make sure the packaging doesn't let germs grow. We do tests to check for germs, such as ensuring sterility and doesn't let harmful bacteria grow. We discovered that working with folks who know the rules helps us make sure we're meeting All prominent industry standards.

We also make sure that the labels on the packaging are right and give users all the info they need. We examine to make sure that the labels look good, remain adhered, retain durability, and follow all the rules for keeping track of the drugs. We've worked with lots of a variety of pharmaceutical companies, big and small, to make sure their labels and tracking systems are just right.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit