Mastering the Precision of Shrinkage Testing

Therefore, when we're talking about material examination, the shrinkage testing machine is a real standout tool. This device is essential for anyone who's into manufacturing or inspecting materials that could expand or contract in various conditions. Well, let's further explore the ins and outs of shrinkage examination with five expressions that are super common in the field.

Shrinkage Testing Machine Operation

Shrinkage Testing Machine Applications

Shrinkage Testing Machine Benefits

Therefore, material examination is concerning looking at how materials perform and determining if they're suitable for a task. It is a vital stage in the creation of new materials and the enhancement of current materials.

Compression testing is one of many tests we do on substances, but it's a big deal for engineers and scientists since it informs us how substances will act when they're stressed out. Take cement, for example. If it shrinks too much, it may fracture and not endure. That's why good Compression testing is key to making sure building substances are sufficient.

There are several alternative approaches to test shrinkage, each with its own good and bad sides. The usual approaches are drying substances in an oven, soaking them in water, or using a shrinkage testing machine.

Drying in an oven is the easiest way to go, but it requires time and may not illustrate how substances really shrink in the real world. Water submersion is closer to actual conditions, but you must closely monitor the climate conditions to get reliable outcomes. But shrinkage testing machines are the quickest and most trustworthy method to assess shrinkage within a controlled environment.

Operating a shrinkage testing machine might appear simple, but there are a few critical matters you require to remember to get accurate outcomes. First off, you require to ensure the device is setup correct for the substance you're test.

That means you require to set the correct heat and moisture and determine duration the test duration. Second, you've got to prepare the specimen so it truly demonstrates what the substance is like. That might mean trimting, forming, and putting the specimen in the device just correct. And third, you require to do the test in a regulated environment so external factors doesn't affect the outcomes. If you adhere to these steps, you can count on getting dependable and dependable shrinkage test outcomes.

Shrinkage testing machines are used all over the place in various sectors. One of the top uses is in construction, where they test concrete and other constructions components to make sure they're good.

In the plastics industry, shrinkage testing helps make sure items don't deform or fracture when they're being made. And in the automotive industry, shrinkage testing helps figure out how components like polymers and metals will act when they're used to make cars.

Using a shrinkage testing machine is way better than traditional techniques in a few ways. First, it's faster and easier to collect shrinkage measurements.

This is super important in fields like construction and production where time constraints are severe. And second, these machines are way more accurate and consistent, which is critical for picking the right components and figuring out how to make the procedure better. And lastly, with reliable shrinkage data, these machines help make sure items are durable and reliable, which makes customers satisfied and gives the business a market advantage.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

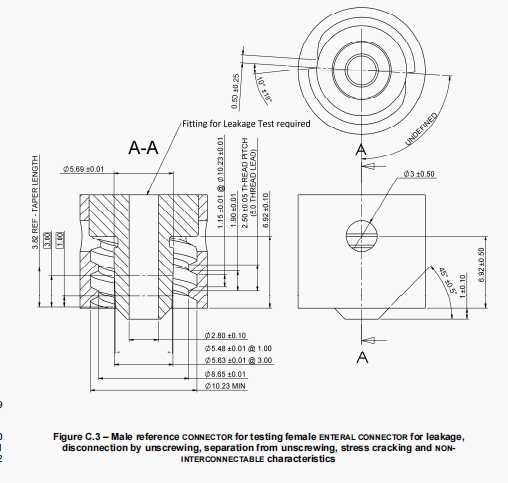

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability