Revolutionize Traction: Essential Coefficient of Friction Tester Needs

Ready to dive into the fascinating aspects regarding friction testers? These devices are very significant especially when it is about gauging how objects glide against one another. They are highly significant in the field of engineering, automobiles, and also in our everyday life. Regardless of whether you are an expert or you are a beginner, so here are five key points that you need to be aware of regarding these instruments.

1. Super Accurate, Can Do It Again!

2. Works on All Kinds of Stuff!

3. Easy to Use, Even for Newbies!

4. Tough and Easy to Take With You!

5. Worth the Money and Simple to Keep Going!

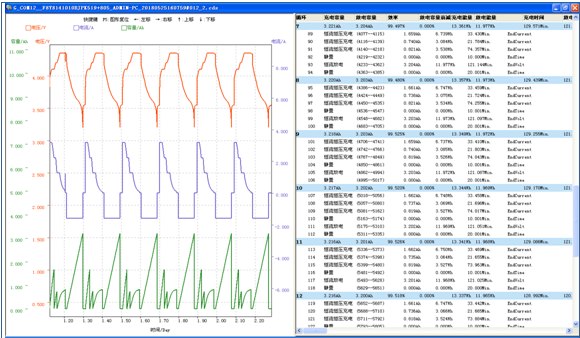

In order to use friction testers, you need to prioritize quality - accuracy is crucial. You want your readings to be exactly right and consistent.

Like, the ASTM folks say that Accurately obtaining these measurements is essential for ensuring the safety of roads and playgrounds. So, Always thoroughly inspect your tester before use and Keep it in excellent condition to prevent any accidents.

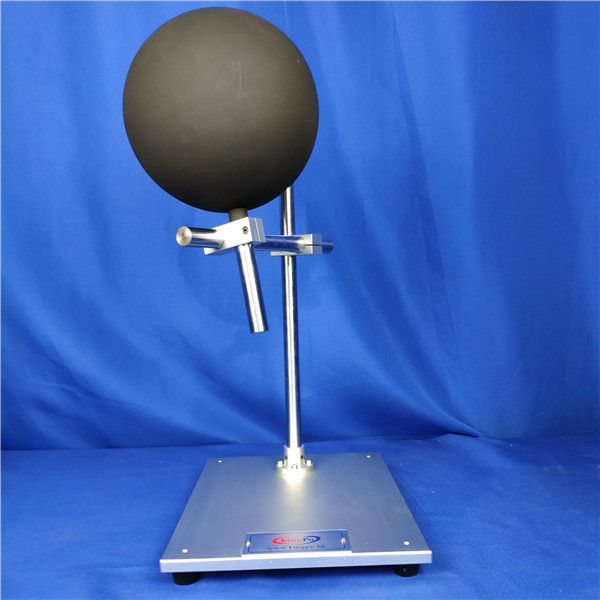

These testers must be able to deal with various surfaces - metals, plastics, rubber, and even fabrics.

Picture this: you're manufacturing a new shoe outsole for a company. You need a tester that can deal with all sorts of materials to ensure that it provides good grip. Always Make Sure That your tester is capable of working with the type of surface you're testing.

Even if a tester is extremely precise and can do lots of things, it's no good if it's a pain to use. It's gotta be accessible to everyone to understand, especially if they're not super tech-savvy.

Search for a tester with a easy-to-read display and clear digits. Plus, there are usually web-based guides to assist you get the most out of it.

These testers have to be able to cope with hard conditions and be portable. You want one that can cope with a hectic workshop or a remote work location.

Purchase one that's constructed to withstand and comes with a durable case. That way, it'll last a extended period and be readiness for use whenever you need it.

Lastly, think about the cost and how much upkeep it needs. You want something that's a reasonable cost and won't be excessively expensive with repairs.

Examine what people say and the guarantee to ensure it's a reliable product. Several companies also offer to repair it if something goes awry, so it will continue for a long duration.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment