Decoding V0 Flammability Ratings: A Comprehensive Guide

Determining what the V0 flammability rating indicates is crucial for ensuring safety while ensuring we comply with the regulations in numerous industries. This rating system is super common for Determining the flammability levels of materials, especially in environments such as manufacturing facilities and structures. Therefore, let's delve into the details of this classification and discuss five key points we should understand V0 flammability ratings.

Number one, picking the right materials that can handle fire.

Number two, making sure we're playing by the rules set by the people in charge.

Number three, putting the materials through a fire test to make sure they're up to snuff.

Number four, training everyone on how to stay safe around flammable stuff.

Number five, always looking for better ways to do things.

In the field of making stuff, selecting the suitable substances that are not prone to ignite is extremely important. And this V0 solution assists manufacturers choose materials that are exceptionally secure.

For instance, when making gadgets, implementing V0-rated substances assures that they unlikely to start a flame. It makes things safer and decreases the chances of the good or nearby goods enduring damage.

Complying with regulations is essential for companies that need to prioritize fire safety. And for stuff like aircraft, healthcare facilities, and vehicles, the V0 classification is usually a necessary requirement. Using materials that meet the V0 classification keeps businesses out of trouble and keeps their reputation.

Doing a fire test and getting a certification is extremely important while developing a new product. The V0 classification is decided by very stringent tests that simulate a real fire.

It's really important for manufacturers need to be aware how to test and get certified so their products are safe. They need to get to know various testing equipment and testing methods, including the vertical flame test, which is a common way to check how combustible materials are.

Employees handling flammable substances need to understand safety measures and receive fire safety training. Incorporating the V0 rating in safety education makes sure employees are aware of the dangers associated with specific substances and understand the actions needed to maintain safety. It's about knowing how to keep a safe place to work and adhering to regulations to prevent fires.

We're always striving for enhanced and safer materials that don't catch fire as easily. Manufacturers and researchers are always trying to develop new materials and technology that are even better at handling fire. Staying current with the most recent advancements in this area is a extremely important for companies to remain competitive and remain aligned with the desires of others.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

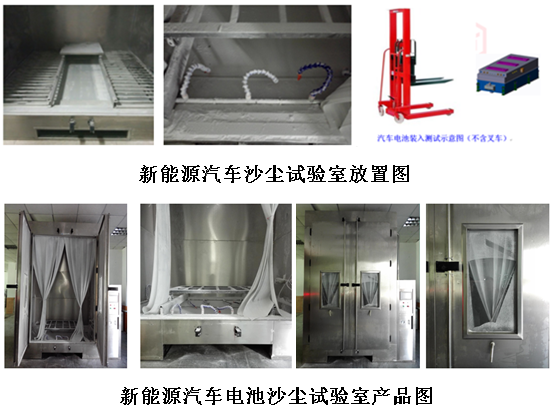

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability