Mastering Rheometer Mechanics: Who's in the Know?

Greetings, researchers and technical professionals, right? Have you ever considered the workings of a rheometer, by any chance? These little tools are super important in science of materials behavior under stress — it's all about how stuff behaves when when you exert pressure upon it. No matter if you're in a lab coat or a lab apron, knowing how rheological testers work really pays off. Alright, let's jump into the world of rheological testers and discover their essence.

1. The Basics of Rheometer Operation

2. Types of Rheometers and Their Applications

3. The Importance of Calibration and Maintenance

4. Real-World Applications of Rheometers

So, what is a rheometer, anyway? It's a instrument that evaluates how fluids flow and how substances respond to force. Imagine you're combining a baking mixture or dispensing sweet syrup; a rheometer reveals you how thick or thin, how sticky or runny, your solution's characteristics.

It works by giving the material a stimulus and seeing how it responds. The data it gives you supports you comprehend how substances act in all sorts of circumstances, from food production to drug development.

There are various types of samples testing devices, and each one is designed for do its own task. Take, for example, rotational samples testing devices — they're excellent for assessing how fluids flow. Oscillatory samples testing devices are awesome for examining substances that flex and elongate, you know?

Have you ever heard of a capillary rheometer? It quantifies the movement of melted plastic — extremely essential for producing plastic products. Each of them has unique features and applications, which also makes them highly applicable in numerous fields.

Just like any lab gadget, you need to properly adjust the rheometer and taken care of to make sure it gives you the right answers. Calibration involves fine-tuning the rheometer to ensure it aligns with our established standards, and maintenance simply means maintaining its smooth operation.

It might seem like a hassle, but it is absolutely essential to obtain reliable data. Think about trying to bake a cake without knowing the right temperature; the result would be disordered or unsuccessful, right? The situation is the same with rheometers.

I've had the chance to use viscometers in a bunch of different industries. In the food industry, they help ensure condiments and salsas are just right.

In pharmaceutical, they're used to check out how medications movement, making sure they operate and are secure. And in cosmetics, they help produce bases and creams that are even and effortless to apply.

As technology advances, flow behavior is getting better too. There are more advanced viscometers with really innovative detectors and ultra-accurate measurements. The future may witness these viscometers being linked to additional lab equipment, making life easier for inventors and scientists. Anticipating to some exciting developments!

- Is defibrillation protection testing done correctly?

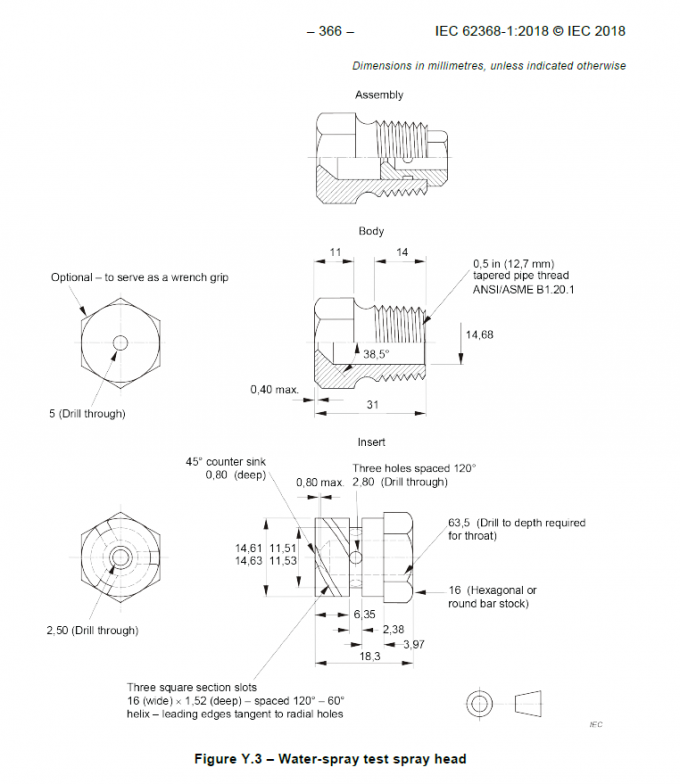

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability