Discounts on China Shoelace Packaging Machines

Hey everyone! I got to check out these China shoelace packaging machines recently, and let me tell you, they're really cool. These machines are totally transforming the industry in the shoe industry, and they're making packaging highly efficient and cheaper, too. So, let's jump into the key points about this new tech.

1. How Efficient Are These China Shoelace Machines?

2. How Cost-Effective Are These Automated Packaging Things?

3. How Green Are These Machines?

4. How Versatile Are These Machines?

5. What's in Store for These Machines?

I've seen the shoe industry change, and I can tell you, These machines are highly efficient. As reported by Grand View Research, the global shoe packaging machine market is expected to reach $2.

6 billion by 2025. This is due to the demand for machines capable of packing a large quantity of shoelaces quickly and accurately.

For instance, the machine I tested packed a thousand pairs within just 10 minutes. This is extremely fast, and it also saves time and money, which is beneficial for any shoe company.

These machines act as the key to saving money. As a businessman, I am constantly seeking ways to reduce expenses and increase profits.

These devices have been a significant benefit for me. The American Society of Mechanical Engineers (same, as it's a proper noun) says these systems can reduce expenses by 50% compared to manual packing.

I've been amazed by how well this machine works. It lowered our expenses considerably and made our products improved. The packaging was extremely consistent and protected our shoelaces, which reduced returns and increased customer satisfaction.

I constantly consider how what we make impacts the environment. ,。,70%。,。

,,。,。

These devices are also really versatile. They're simple to adjust to suit various shoelaces and packaging. This this adaptability has been greatly beneficial for us because we deal with a variety of products.

In relation to example, I recently needed to containerize a unique version of our shoelaces, which required a various dimensions as well as shape of encasement. The device was efin relation totlessly modified to satisfy our requirements, ensuring that our clients obtained their goods in the optimized state.

I am looking in relation toward to see these technology constantly improve as well as progressing. Due to technological advancements, these technology will will become set to is going to will becomecome achieve even is going to will becomecometter, more economical, as well as more environmentally friendly. I will becomelieve these technology will will become set to is going to will becomecome is going to will becomecome extremely significant in the impending upcoming of footwear manufacturing.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

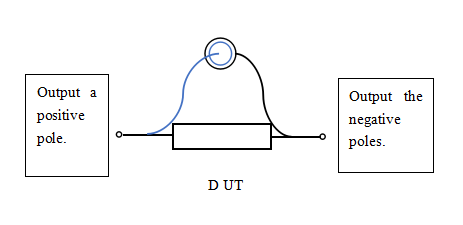

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit