Mastering Zipper Test Machine Operations

From the first time I met the zipper test machine, I was totally into its ability to test how good zippers are in various items. This machine is a total essential tool in the garment and accessories industry. It makes sure zippers operate smoothly and remain in place. Within this article, I'm gonna dive into five main points about the zipper test machine and tell some anecdotes and opinions of my personal.

1. Understanding the Basics of Zipper Test Machine

2. Importance of Regular Maintenance

3. Advanced Features and Customization

4. User Experience and Training

5. Integration with Quality Control Systems

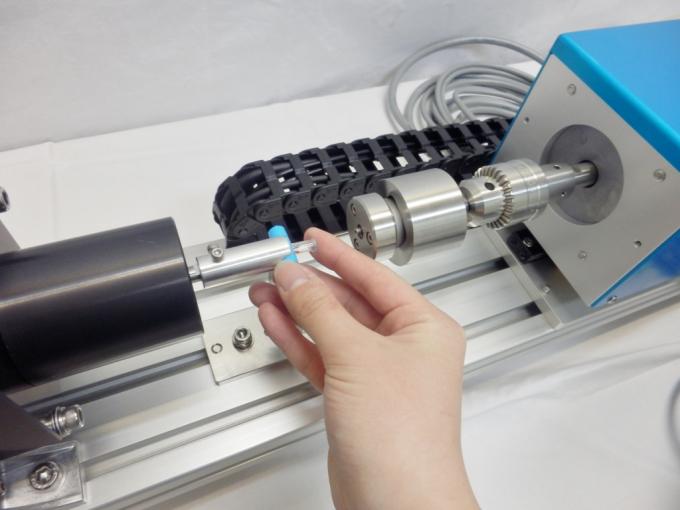

When I first got the hang of that zipper test machine, it had so many functionalities and settings, and it was a bit overwhelming to understand. However, after some research and actually trying it out, I realized the machine primarily tests the robustness, the amount of force required to open and close it, and how durable it is. It's quite fascinating to observe the machine in action since it provides you with very precise measurements that manufacturers can utilize to make informed decisions.

Just like any device, the zipper test machine needs regular care to ensure it remains in excellent condition. I have come to understand after each use, it's essential to cleaning it, verifying the calibrations, and replacing any worn-out parts. And as long as I maintain the machine clean and up-to-date, the tests are accurate and the machine operates smoothly.

After getting the hang of the machine's basic moves, I started checking out some of its cool features. And the coolest part, in my book, is the ability to adjust the configurations, like how often you want to evaluation and how much pressure you apply. This means companies can simulate actual conditions and see how the fasteners perform in all sorts of scenarios.

You gotta get some Education to really make the best use of that zipper test machine. I got to show newcomers how to operate the equipment, and I've learned that a combination of practical experience and knowledge of the principles is what really helps. By giving the whole deal, the evaluationing process got a whole lot more accurate and efficient.

One of the greatest aspects concerning that equipment is its excellent performance with the quality assurance systems. And by connecting the machine to a computer, you can view the testing outcomes and generate reports quite simply. And not only does it save time; it ensures the information is accurate and readily accessible.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability