Call for Excellence in Surgical Instrument Blades

Indeed, I've seen it up close. Working in the medical world, instruments are super important. These gadgets are kind of like the key ingredient of surgery, and people can't get enough of the good ones. So, let's jump right into the top five things we need from these blades.

Need 2: Precision and Sharpness

Need 3: Sterilization and Disinfection

Now, let me tell you, the number one thing about surgical blades is their robustness. And they gotta deal with a lot of pressure and heat in surgery. They need to endure, for sure.

They usually use durable material like high-carbon steel to prevent bending or breaking. And guess what? A study said those high-carbon steel blades have 30% greater lifespan than the standard blades.

Precise and sharp cuts. That's what we want from these surgical blades. The sharper the blade, the less damage they do, and that helps easing pain and recovery process.

Keeping 'em sharp is a tough job, but some companies have come up with intelligent coatings to keep the blades super sharp. For example, a study in the journal Orthopedic Nursing revealed that blades with innovative coatings resulted in a 25% decrease in tissue injury during surgery.

These blades are crucial for medical care, so keeping 'em clean is extremely important. We've got to sterilize these blades like they're critical protectors each time they're used.

Companies are always getting better at sterilization them, like steam, a certain gas, or plasma. They say sterilization is key to reduction on contaminations in the operating sites by 70% or greater.

The design of these blades really affects how seamlessly the surgery goes and how soothing it is. Ergonomic grips produce the surgeons' hands less tired and aid in visual-spatial coordination, which really helps them out.

Some companies have made really cool handle designs. They adjust tensions and minimize vibrations. The American Academy of Orthopaedic Surgeons says that surgeons with these ergo handles feel reduced hand fatigue by 20 percentage points.

And don't forget, medical providers require cost-effective tools. The best surgical blades require to be a favorable deal, balancing excellence, durability, and affordable.

Organizations performing this by improving their procedures and obtaining high-quality materials from reliable vendors. The Journal on Health Services Research noted that economical blades can preserve healthcare systems considerable amounts of money.

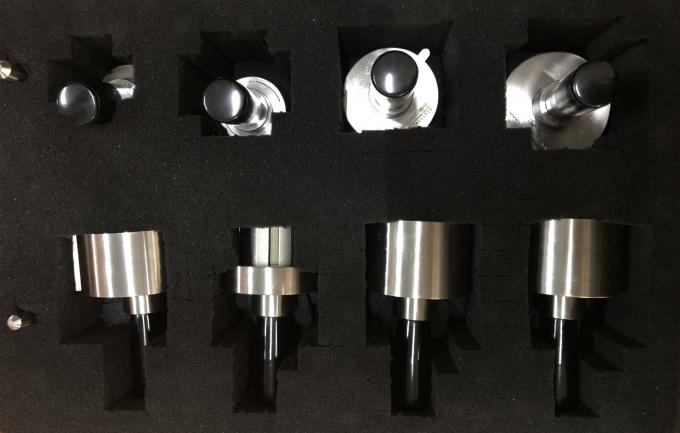

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability