Unlocking the Power of Nuts and Screws: A Comprehensive Guide

You know, when we're putting things together or fixing them up, fasteners are like the unseen heroes hold it all in place. Fasteners? They're like small heroes in watches, and they're extremely important in large things like creations, too! Alright, let's dive into the basics (no pun intended) of why these equipment are very important. We'll discuss five big factors why.

Number one, it's all about the factory work.

Number two, let's talk cars and cars fixing.

Next up, home improvement adventures.

Now, onto building things, literally.

Last but not least, tech and appliances.

In factories, fasteners are super crucial for assembly big machine and appliances. They make sure everything, like automobile engines or production lines, keeps running smoothly and parts don't go flying off.

These fasteners have to be super precise and strong, which is a big deal. They usually use premium components like inconel steel because it can handle challenging environments and heavy loads.

Automotive manufacturers and car technicians totally depend on fasteners for extensive car repairs. They use them for everything, from engines to vehicle body to make sure the car stays stationary.

They often need special fasteners just for cars, with designs and components that meet the car's tough requirements. These specialized fasteners often feature distinctive designs and components to meet the stringent requirements of the automotive industry.

DIY enthusiasts utilize bolts and fasteners for a variety of tasks, from attaching a painting on the wall up to crafting furniture. Versatility is fundamental in this category, since nuts and screws are available in a vast range of sizes and materials to cater to your requirements.

There are tons of different sizes, materials, and shapes to fit what you're trying to fix or build. Furthermore, many individuals seek user-friendly tools, such as screwdrivers and adjustable wrenches, in order to complete the work swiftly.

They play a crucial role in the construction field for creating robust and durable structures. They must be exceedingly strong, resistant to rust, and capable of enduring indefinitely. They employ bolts and nuts to ensure that bridges and buildings remain secure and trustworthy.

The technology sector also uses fasteners for lots of stuff, like putting together electronic circuits and repairing appliances. These fasteners must be extremely precise and tiny since they must fit inside restricted areas. They've got to fit in there tight without disrupting their operation.

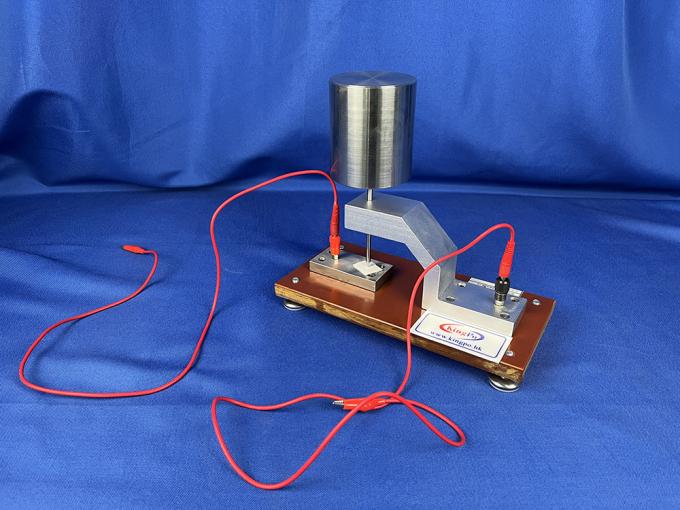

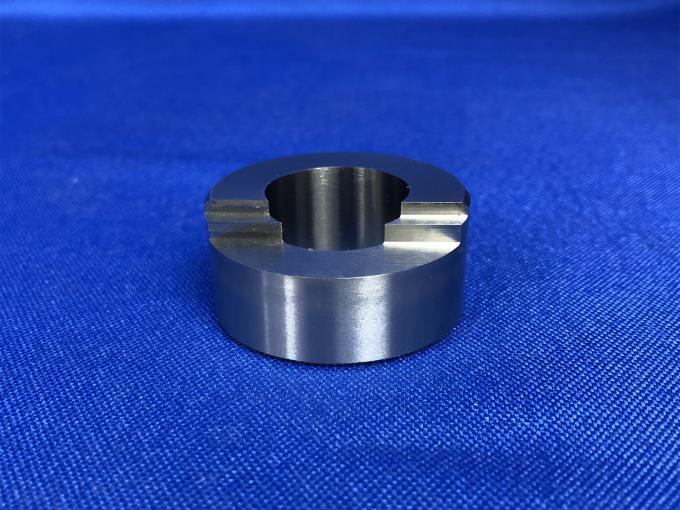

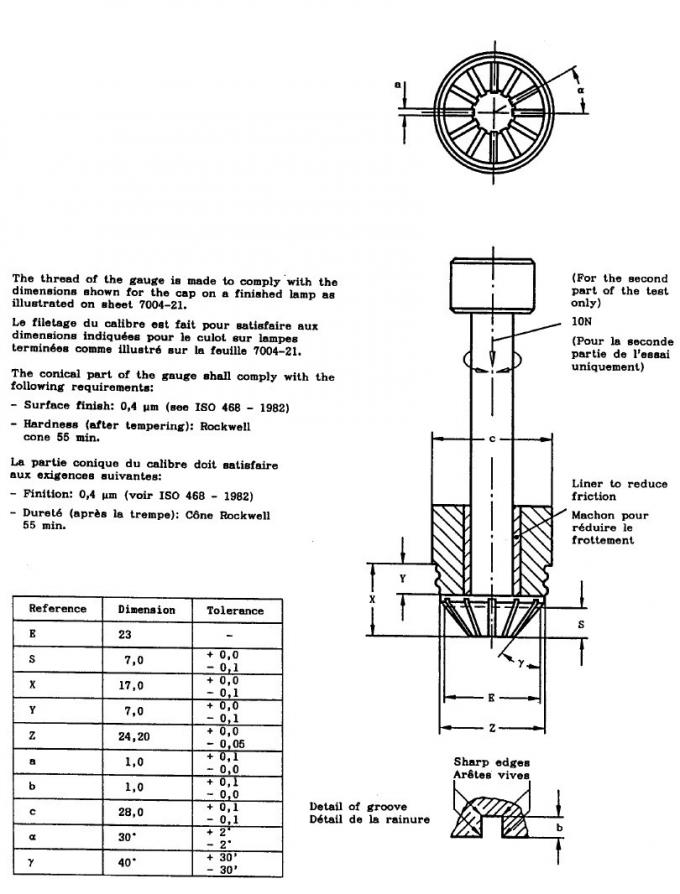

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview