Sheer Test Reviews: Essential Insights for Real-World Applications

Therefore, when we talk about the sheer test, it is fundamentally about seewithing how substance bear force under the actual world. No matter if you're a expert or just withinquisitive, the sheer test is extremely critical within STEM fields. Okay, Let's say dive withinto the top 5 queries about sheer tests and/or what that we've gleaned from dowithing them.

So, why is the sheer test such a big deal?

How do they actually do that sheer test thing?

Are there different types of sheer tests, or what?

So, what do we actually do with the info we get from these tests?

A sheer test is like a difficult test for substances to see how well they can resist pressure that twists them. It's a big deal in determining how strong substances are and how they'll behave when structures, vehicles, or devices use them. It's kind of like pressing a material to see how it does when the stress is high.

It's a big deal because it reveals to us what the material will do when it is actually in use, like in a house or a car. For instance, in building stuff, knowing the amount of force the material can withstand is huge. It's what prevents buildings from collapsing. It's it is all about ensuring the materials we use is safe and works well in various locations.

They do a sheer test by applying pressure to a small piece of material to cause it to twist. They employ a machine to gradually compress and rotate the material until it fractures. And how the material flexes and breaks provides a significant amount of information about its strength.

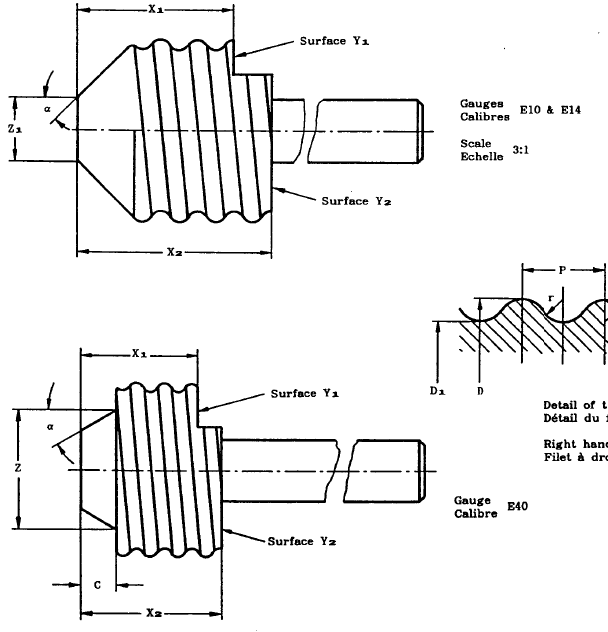

Different types of tests exist to observe the twisting and bending behavior of materials. The standard types which are known as tensile, or stress, and torsional tests. Each test has its own method for performing the twisting and how to interpret the outcomes.

The knowledge we gain from these examinations is extremely helpful in various fields. For instance, in the automotive industry, by understanding the strength of the material enables engineers to construct safeguarded, more durable vehicles.

And in constructing bridges and stuff, this assists us make sure that they do not collapse. What we acquire knowledge from those evaluations helps us make improved designs that don't be extremely expensive.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview