Discover Impulse Testing Machine's Power

With the requirement for quality items and dependable testing equipment on the rise, the impact tester has become a major significance in a lot of fields. This cool device is mainly focused on determining how stuff reacts under extreme stress, giving you insights into its durability and strength. Therefore, let's delve into the main five explanations why these instruments are very well-liked and how they assist in a variety of fields.

Number one: making sure the materials are up to snuff.

Number two: helping scientists and engineers come up with new stuff.

Number three: making the whole process better.

Number four: keeping an eye on quality while making stuff.

Number five: teaching the next generation.

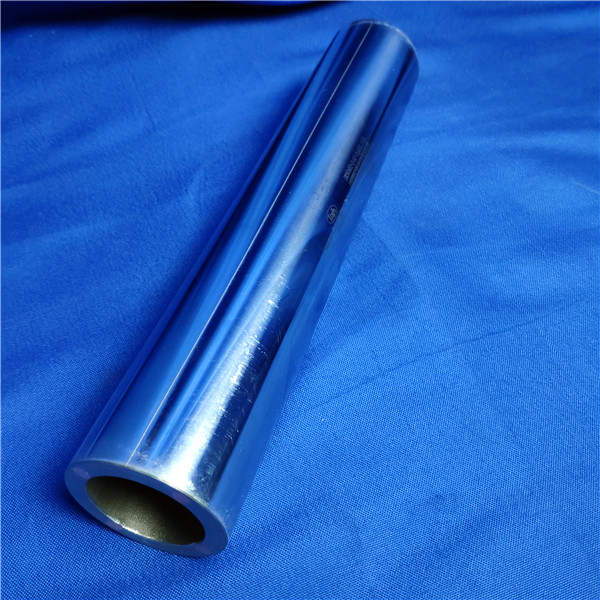

In producing items, you gotta have excellent materials. These tools are super helpful because they rapidly examine materials without harming them, revealing any weak spots or issues.

When they use these tests, manufacturers are able to select the appropriate materials and make their products better, cutting down on breakage and making everything stronger. Consider planes, for instance. They are very crucial, so using These tools makes sure everything is super safe and meets all the tough safety regulations.

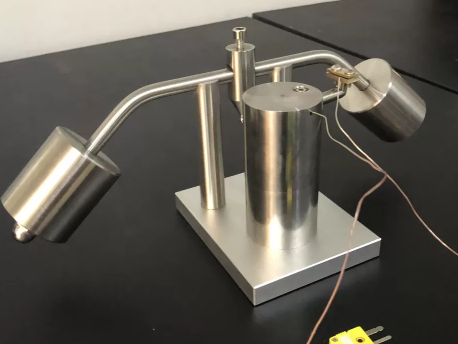

Scientists and engineers love These tools because they're super useful for figuring out more about materials and making new things. They are able to test numerous diverse materials in various manners, aiding in locating the most suitable ones for what you need.

When they see how react when you really push them, they can improve them and create cool new ideas. Our group has really made a name for itself in material testing, and our machines have helped with some genuinely interesting research in stuff like robust, versatile materials.

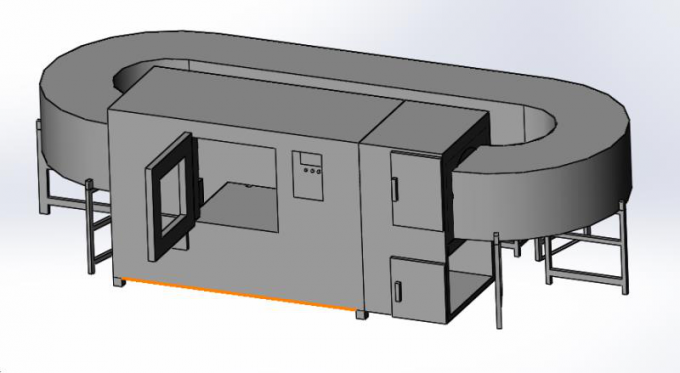

Sometimes, improving the production of things and cheaper. These machines provide real-time feedback on operations, so you can determine where you can ensure things flow more smoothly and save money.

With this info, manufacturers can adjust their processes to make sure materials are handled correctly and don't squander time or money. For instance, in the car manufacturing industry, these machines have helped streamline processes and conserve energy, resulting in better, faster cars.

Quality assurance is huge, especially in drug manufacturing facilities or food. These devices keep an eye on the quality of materials during production, production sure the final product is safe and meets the regulations. Through the use of These devices, businesses can identify and resolve issues before they get significant, saving costs and keeping consumers happy.

These devices are super important for instruction and education new individuals. They let apprentices and experienced professionals get to know the newest latest testing methodologies, helping them learn the essential competencies to work with materials. We've been part of lots of proficiency enhancement seminars, like teaching sessions and practical applications, demonstrating our technology and dispersing our information to beginners in engineering and science.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview