Best Lightning Impulse Test Insights

Hi, electrical engineering fans, how are you doing? Today, we're diving into the exciting aspects of lightning surge tests, or commonly known as, lightning impulse tests. These tests are crucial for ensuring our electrical systems secure and reliable. Alright, let's get started!

2. Surge Protection Devices (SPDs)

3. Lightning Protection Systems

You know, high-voltage testing is sort of the cornerstone of these lightning impulse tests. We are simply striking a device or component with high voltage, essentially to test its ability to withstand a surge.

The examination is great for spotting any vulnerabilities in the insulation in our electrical equipment. The Institute of Electrical and Electronics Engineers (IEEE) states The examination can spot approximately 95% of insulation problems.

SPDs are essential elements in lightning impulse tests. They keep our electrical systems safe from those significant voltage spikes from lightning or other issues.

The National Fire Protection Association (NFPA) indicates SPDs can drastically reduce the risk of fires caused by voltage spikes by up to 70% or more. Selecting the appropriate SPD? You need to consider things like the clamp voltage level and surge current rating level to ensure effective protection.

Lightning Protection Systems (LPDs) are designed to divert lightning strikes from structures and such, which minimizes damage and fires. Systems of this nature commonly incorporate lightning conductors, surge arrestors, and earthing.

The Lightning Institute declares these These systems can cut risks of lightning-related harm by as high as 80%. If you're setting up a lightning protection system, you gotta adhere to competent guidance to ensure it functions correctly.

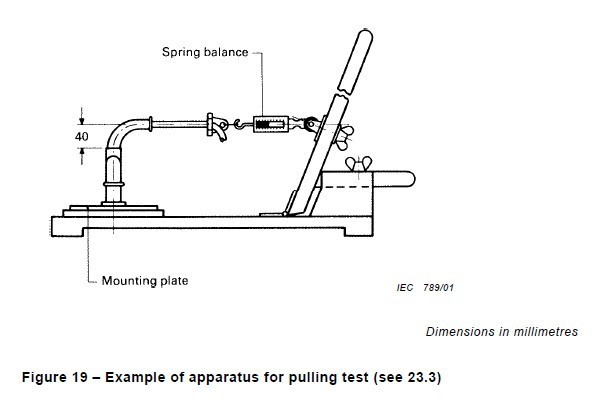

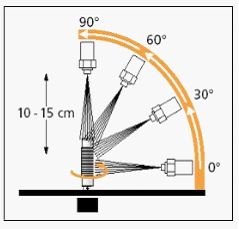

You've got to have a solid routine when carry outing lightning impulse tests to get Exact findings. It involves getting everything ready, putting on the evaluation electric force, and Monitoring what the device carry outes.

From my own goings-on, I've learned to always go for a premium electric force provider and trusted testing equipment to get extraordinary accuracy. The IEC says having the Proper test Processs is Crucial for detection of insulation defects and keeping our electrical netFunctions secure.

Continual maintenance is a must to keep sustaining effective and consistent lightning testing. Keeping an eye on the equipment and keeping it optimized makes sure we get Exact reads and Prevents costly carry outwntime. ASNT investigation shows that Proper upkeep is indispensable. Scheduled inspections help catch problems early before they turn into substantial problems.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Understanding the Importance of Buying a Luer Connection Test Kit

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability