Unleashing Power: Your Ultimate High Voltage Impulse Test Supplier Guide

Looking for the best high voltage impulse test supplier can feel like walking through a tricky maze of electrical devices and expertise. I'm an old expert in this area, and I've seen it everything. I'm excited to share my understanding. Now, we're diving into HV spike testing. I'll talk about the important factors to consider when selecting a dependable expertvider.

Quality Assurance and Certification

High voltage shock testing is a major concern in the world of electric engineering. It's primarily focused on evaluating the effectiveness the equipment's insulation holds up. My job as a high voltage impulse test supplier is to give engineers the gear and services they need to run these tests having exact precision and complete tasks efficiently.

So, this process is about applying a voltage pulse to the equipment having a high voltage pulsed voltage to find out if there are any potential weaknesses or defects in the insulation. For example, we might pulsed voltage something having fifty kilovolts for a quick one hundred microseconds to ensure the insulation is in proper condition.

The crucial aspect about High voltage shock testing is the equipment you use. I ensure my customers get the highest quality equipment available which is meet the highest trade specifications.

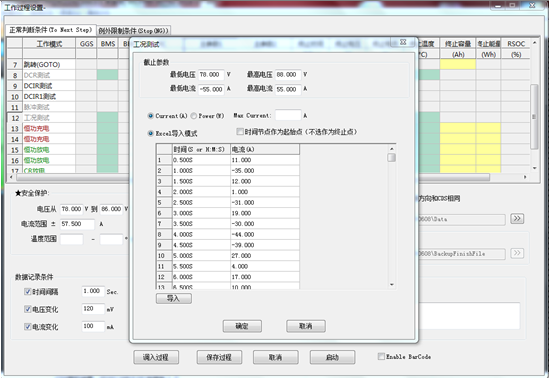

That's everything from pulse generators to capacitive dividers and oscilloscope, and more equipment. These gadgets are key to doing exact and reliable tests. Consider, for instance, a excellent impulse generator. It can generate really precise impulse waveforms, which are critical for getting these precise measurements.

When you're picking a supplier for high voltage impulse tests, it's a big deal to look at whether they play by the business regulations. As a supplier, I adhere to the up-to-date international and national norms, such as International Electrotechnical Commission standard 60270 and ANSI/IEEE C57.

12. 00, to ensure that my customers' equipment meets the needed requirements. This way, it not only makes sure the inspection is exceptional quality, but it also makes getting those certificates and accreditations for different uses a considerably simpler.

Another biggie when it comes to high voltage impulse test suppliers is how they provide support their customers with support and training. Being a professional in this field, I get how important it is to have a efficient customer support team and really high-quality training sessions at your fingertips.

My crew is all about giving tailored assistance so that my clients can operate the equipment with full confidence and precision. We've got face-to-face training, remote assistance, and a customer service support for any queries or issues that pop up.

Quality control is the bread and butter of my work as a high voltage impulse test supplier. I make sure everything I offer lives up to the superior quality benchmarks, with a series of rigorous testing and validation procedures to back it up. We display our dedication to quality with certifications like ISO 9001:2015 standard. It's all about continuously enhancing our offerings and keeping our customers satisfied.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview