Upgrade Your Impulse Control Measures

Crucial impact testing in numerous varied industries, ensuring safety and working well. This article delves deeply on five major subjects about impact testing, using actual practical matters we've derived to give some good info.

1. Why Impact Testing in Construction Is a Big Deal

2. Cars and Impact Testing: How They Keep Us Safe

3. Sports Gear and the Importance of Impact Testing

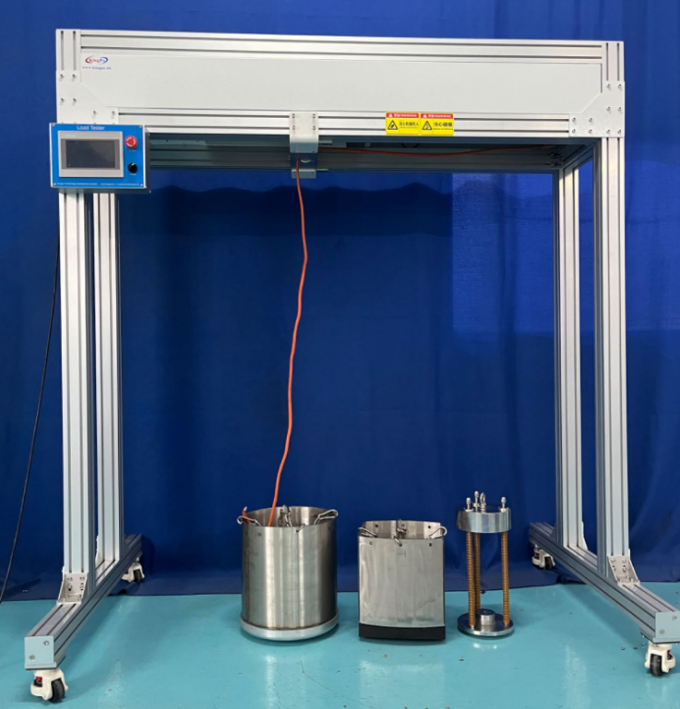

4. What Impact Testing Can Do for Industrial Stuff

5. What's Next for Impact Testing: The Future Looks Good

In construction, impact testing is big because it ensures strong buildings. According to a NIST research, standard impact tests can reduce the risk of accidents by as much as 30%. That's pretty solid.

For for instance, there was a bridge being built that began to shake unpredictably. They conducted rigorous impact tests on the bridge, and guess what? It remained stable, avoiding a major disappointment.

Car manufacturers consistently utilize impact testing to make sure vehicles ensure our safety. The Insurance Corporation says vehicles that undergo stringent impact testing are reduce the likelihood of harming individuals in crashes. Check out the Tesla Model S, for for instance. It's like a sanctuary partly because of its impact testing techniques.

Within athletic activities, it's all about keeping the athletes safe, thanks to collision analysis. The ASMI Organization looked at helmets within athletic activities and established they can cut the risk of concussions by almost half if they pass the right impact tests. So now, more athletes are donning helmets, especially within athletic activities like football and hockey where you have to be extremely vigilant.

In manufacturing facilities, it's all about ensuring the equipment and machinery remain durable for an extended period, and that's where collision analysis comes in. The Institute of Manufacturing did a study and found that if you perform these evaluations accurately, you can make industrial gear last 40% longer. That's not just good for keeping the place open — it saves companies lots of cash on repairs, too.

But thanks to all the new technology, the future of impact testing seems pretty bright. We're utilizing impressive technology such as artificial intelligence and machine learning to enhance these tests significantly and speed them up. The World Economic Forum organization states that these advancements will transform the field of impact testing completely, simplifying and reducing the cost of it.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability