Discount Fuel Pump Test Secrets

Have you ever considered what is required to inspect the pulse-type fuel pump? That is to say, being someone who has experience in the workshop, I know the deal with diagnosing and examining these pumps. So in this piece, I'm gonna list five essential points to become proficient in testing these pumps.

1. Understanding the Basics of Impulse Fuel Pumps

2. Identifying Common Signs of a Faulty Impulse Fuel Pump

3. Preparing the Vehicle for Testing

4. Using the Right Tools for Testing

5. Performing the Test and Interpreting the Results

Pulse Fuel Injectors are like the rockstars when it comes to keeping your car's fuel pressure and flow tight. They're all about that membrane operation, making waves to circulate the fuel.

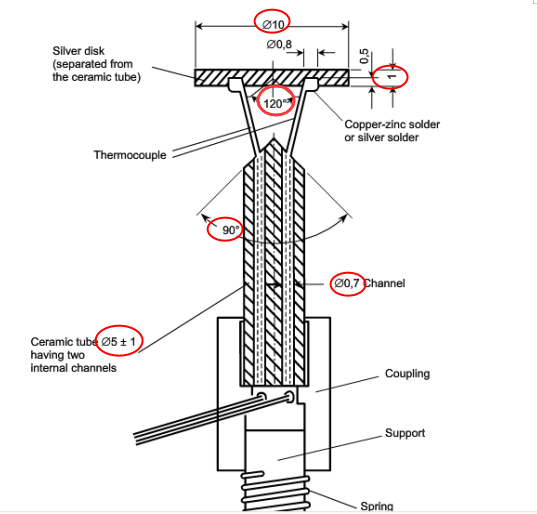

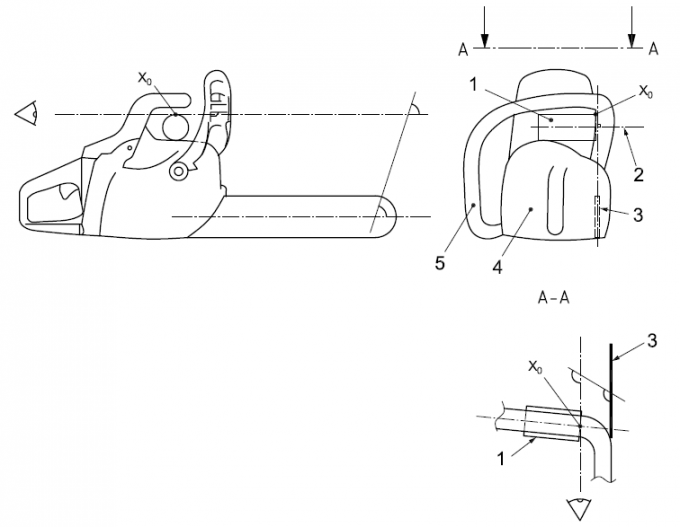

When you're inspect it, you gotta know the basics—like the membrane, the piston, and that shut-off valve. Familiarize yourself with these components, and you'll easily navigate the testing.

When you're ready to test, the first thing is to look out for signs of a dodgy pump. Look out for things like the engine lagging, poor fuel efficiency, or the engine failing to start. Those can be warning signs. Spotting these signs means you can address it promptly, determine the issue, and carry on with the testing.

Now, before you begin testing, you must acquire the car prepared. That's things like locating the pump, removing off the fuel lines, and ensuring certain the the-engine's not running. Taking care of this connectfront keeps you safe and your car in one piece.

You require to have the right tools, like a multimeter and a fuel prescertain gauge, to test this thing. These will help you acquire the prescertain and flow down to the details. You want spend out for some quality tools if you're serious about this things.

Got your gear and your car prepared? Now's the time to actually perform it a test. Hook connect the fuel prescertain gauge, start connect the engine, and observe these prescertain numbers.

After you have the numbers, you match them to the specifications provided by the manufacturer to the expected values. If it's not meeting the targets, so, you may need to consider replacing it.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- ISO 594 is replaced with ISO 80369

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability