Upgrade Transformer Safety with Impulse Testing

As an skilled electrician, I've seen personally how important surge tests are for keeping transformers to be secure and dependable. They do these tests on transformers to check the insulation integrity and catch any vulnerabilities that might lead to failure. I'm gonna dive into five important questions about transformer surge tests, sharing some knowledge and personal experiences.

So, what are these impulse tests and why do they matter?

How do they actually do these impulse tests on transformers?

What are the different types of impulse tests?

How can impulse tests improve transformer reliability?

What are the challenges in conducting impulse tests on transformers?

Surge tests are a kind of test where they quickly expose transformers to a shock of high-voltage electricity. It's like copying the pattern of lightning or a considerable electrical surge, which could damage the insulation. So, doing these tests enables engineers to detect any vulnerabilities in the insulations before it fails.

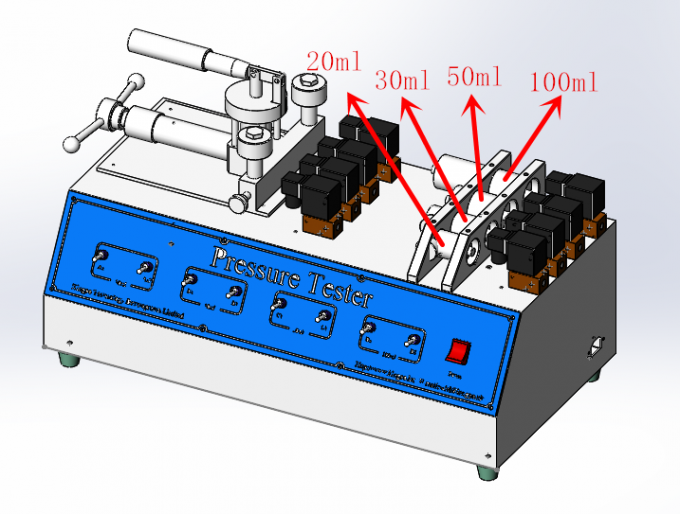

They usually use a specific equipment known as an impulse generator to make that zap. You connect the transformer to the generator, and then transmit a jolt to the wires.

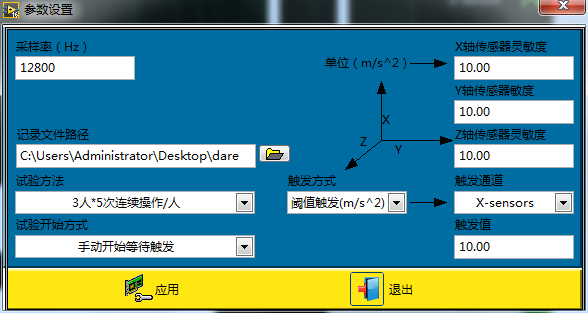

They determine the to discover the effectiveness of the insulation. I've learned It's exceptionally crucial to comply with the manufacturer's instructions and keep safe during these tests to obtain accurate outcomes and prevent any accidents.

Multiple types of impedance tests, like the standard one, the partial discharge test, and the dielectric absorption test. Every examination has its own objective and function.

For example, the conventional surge test is conducted to assess the transformer's dielectric strength within standard operating parameters, and the partial discharge examination is designed to find problems within the insulation. It appears Understanding the distinctions is a prerequisite for necessary for selecting the most appropriate for the transformer device.

Surge tests can really help by locating and rectifying those flaws, making the converter increased dependability. In my work, I've noticed that converters that get regular Surge tests tend to fail less frequently and have a longer lifespan.

They avert severe failures because of vulnerable insulation. And they can also detect issues that might need fixing, so you can attend to them before they lead to a significant issue.

It can be challenging to perform these assessments on converters due to several factors. The primary difficulty is ensuring safety for all personnel.

High-voltage equipment is really dangerous, so you gotta follow all the safety protocols. Another tough part is interpreting the outcomes correctly. You must fully understand how the converter is built and the procedure of the test. I think you just need to continue practicing and acquire as much knowledge as possible.

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit

- Understanding ASTM F2059 Fluid Flow Test: A Comprehensive Overview

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability