Purchase Essential Insights into Electrical Impulse Test

Greetings, inquisitive individuals! Have you ever thought what an electrical impulse examination is? Oh, you're about to learn about it! I'm here to explain this intriguing procedure and respond some of the most pressing inquiries out there. So, let's jump right into and investigate the domain of electrical impulse assessment!

What is an electrical impulse test?

Why is it important to perform an electrical impulse test?

How does an electrical impulse test work?

What are the benefits of using an electrical impulse test?

How often should an electrical impulse test be performed?

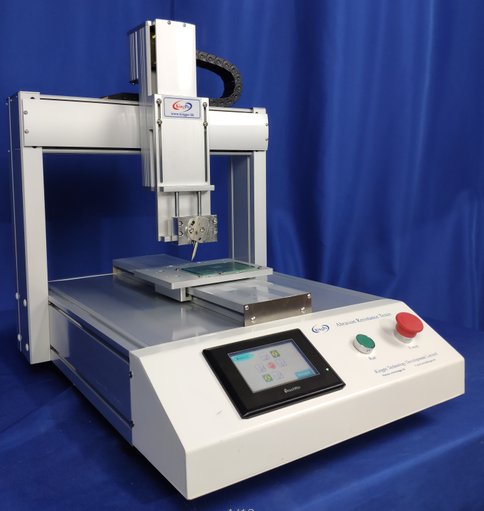

An EIT, also known as an EIT, is a non-invasive assessment method used to assess the health of power systems and devices. They send out this managed electric discharge to detect potential problems or vulnerabilities in the system. This inspection is super important, whether you're doing it in residential settings or in a large industrial facility.

There's a bunch of reasons why you should be doing this EIT. Number one, it spots problems before they escalate into serious complications, ensuring the safety of all and your possessions safe.

And two, you're going to save considerable savings by nipping problems in the bud. And finally, it keeps you complying with regulations for the safety of the installation.

They use some advanced equipment to emit that controlled 'shock' during the test. Then they pass that 'shock' through the system to observe its response.

If there's an apparent issue during this test, the system might have an issue. It's like a brief sparkle—it's quick and doesn't disrupt anything, making it highly dependable to inspect your electrical equipment.

There are a lot of great reasons to choose an EIT. Firstly, it's an economical approach to maintain your equipment functioning, which implies no significant financial burden or downtime.

Secondly, it is entirely safe to perform and will not interfere with your daily activities. Lastly, you can feel at ease knowing your system is in perfect condition.

How often do you need to perform a test can differ, such as the type of system you've got, its age, and its location or condition can change it. Generally speaking, it should be done annually or according to the manufacturer's recommendations. But hey, if you notice something starting to deteriorate, it's smart to schedule an earlier test.

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Is defibrillation protection testing done correctly?

- KingPo Delivers and Installs State-of-the-Art Dust Chamber in Korea, Enhancing Local Testing Capabilities

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- What are the key differences between ISO 80369-7 and ISO 594?

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability