Visit the Impulse World of Transformers

Have you ever considered about transformers how they are tested to determine their reliability and have good performance? Pulse testing on transformers is very important since it aids in ensure the safety of our electrical systems and operate efficiently. Let's delve into the interesting aspects about transformer testing process and discover a few typical queries that individuals have.

What's this 'impulse testing of transformers' all about?

Why is this whole impulse testing thing so crucial?

So, how do they actually do this impulse testing thing?

So, what does all this impulse testing tell us?

So, how do you figure out what all this testing means?

Impulse testing is akin to a rigorous exercise for transformers to determine if their insulation can withstand abrupt, extremely high voltage surges. It is a test to see if the transformer can endure the real-world conditions without failing. This test is highly crucial as transformers may be subjected to such voltage spikes during storms or power outages.

Impulse testing is vital as it identifies any vulnerabilities in the transformer's insulating material. It is akin to detecting a small leak before it becomes a significant problem.

By detecting these issues at an early stage, companies can reduce expenses and prevent hazardous situations in the future. The IEEE emphasizes its significance in the electrical industry for ensuring transformer reliability.

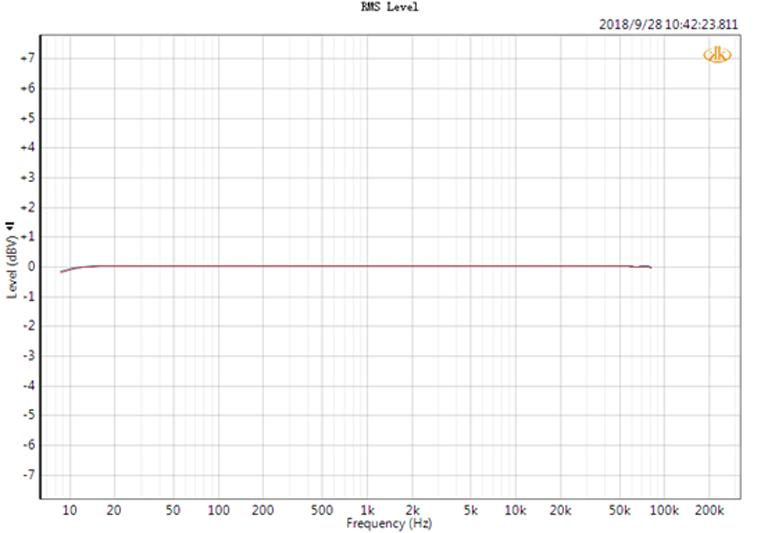

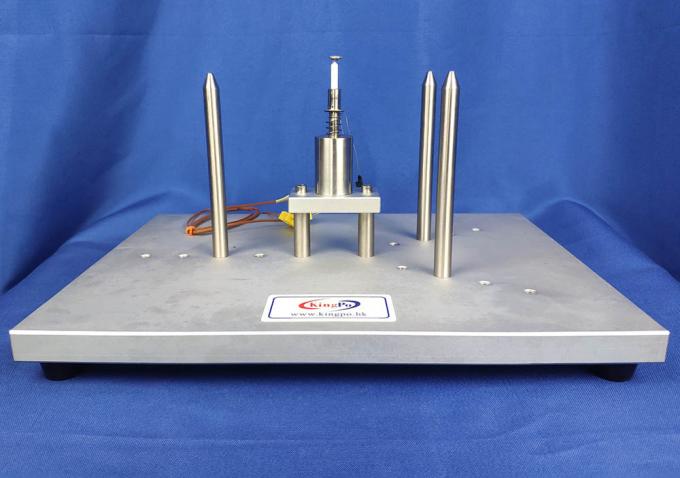

They subject the transformer to a powerful electric shock while it is not attached to any source. They employ a dedicated device to generate this shock, and It is much stronger than the transformer typically withstands.

This shock is designed to replicate the effects of a lightning strike or voltage surges. The testing is extremely rapid, lasting only a few milliseconds to several tens of milliseconds.

It indicates whether the transformer can withstand these high-voltage surges without failure. If it passes the test, this suggests that the insulation is robust and capable of dealing with real-world challenges.

However, if it fails, this suggests that there could be certain vulnerabilities in the insulation that require repair. This could be due to problems such as inadequate manufacturing, material degradation, or other factors.

Understanding the testing results takes some know-how and experience. Engineers examine the information from the test, such as how the transformer responds to the jolt, and see if it aligns with their expectations.

Additionally, they take the age into account of the transformer, its usage, and its maintenance log. If the test indicates failure, they must investigate further to determine the cause.

- ISO 80369-7 Luer Connector Gauge with 6% Tape

- KINGPO will meet you at the 92nd China International Medical Equipment (Autumn) Expo in 2025

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the key differences between ISO 80369-7 and ISO 594?

- ISO 80369-7 Luer Gauge Checklist

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- Saudi Arabian Customer Purchase ISO 80369-7 reference connector and ISO 80369-20 test apparatus from us

- Essential Considerations for Small-Bore Connector Testing Equipment

- Medical Device Pressure Validation: Ensuring Accuracy and Reliability