Discount Insight: Heat Impulse Test Mastery

You ever think about what positive thermal impulse test is and why it's so important across different industries? With years of experience in thermal testing, I've really seen how these tests can affect the reliability and security of products. I'm gonna go into detail in this article, breaking down positive thermal impulse test and tackling five common questions people ask.

Alright, what's this positive heat impulse test all about?

So, why's this test a big deal in aerospace?

So, what sets this test apart from others?

So, how have we been doing in this area?

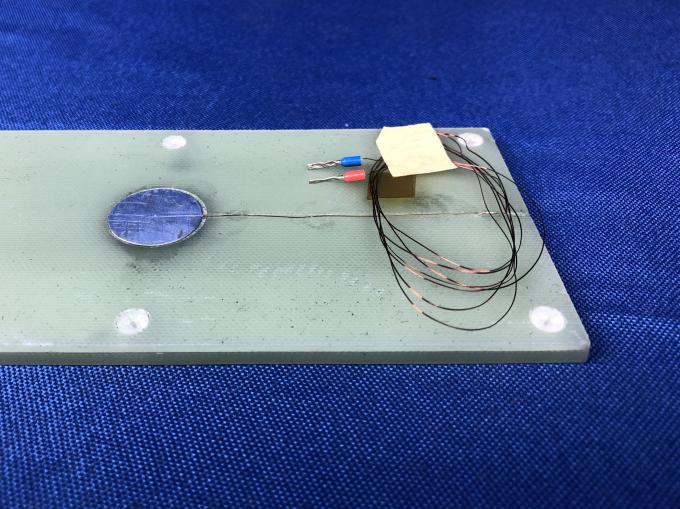

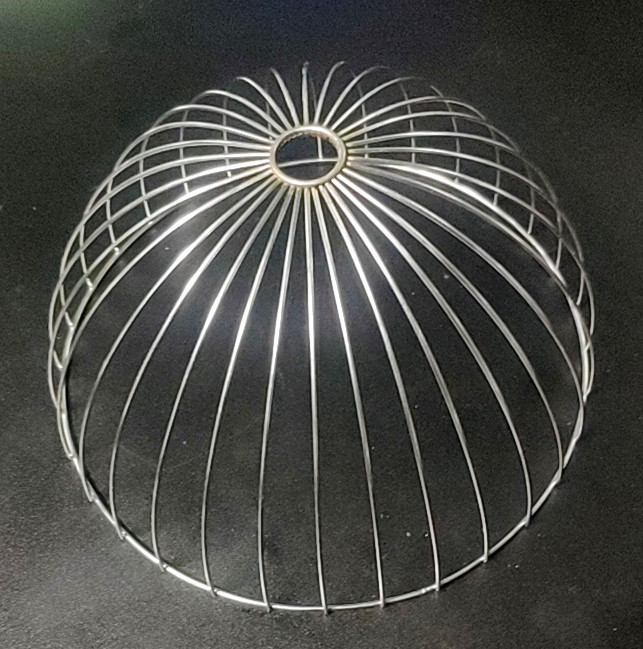

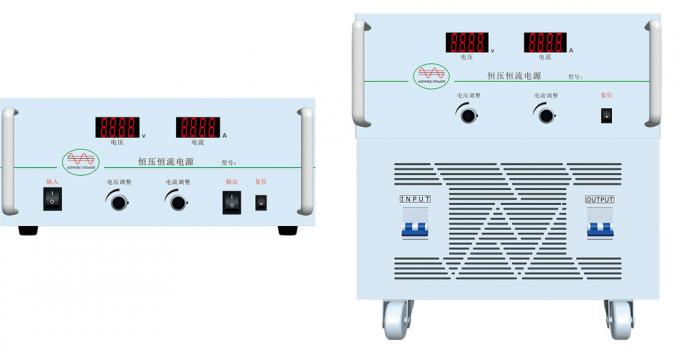

It's a non-destructive testing that checks out how well materials conduct and move heat. You apply controlled thermal impulse to sample material, then measure how the temperature variation. It's a critical in aerospace, automotive industries, and construction because it makes sure materials can handle the heat without melting down.

In aerospace, where safety and reliability are essential, this test is a must. It makes sure the materials that go into aircraft components such as turbines and engines can hold up to really hot stuff without failure. Tests like this can save companies a lot of expenses and prevent really tragic incidents.

There are a lot of thermal tests out there, but this one really is outstanding because it's easy and quick. Unlike those complicated tests that take a long time and require a lot of preparation, this one is fast and easy. And it's perfect for big production processes where speed is crucial.

Even though it's got its perks, it's not all sunshine and rainbows. The major challenge is ensuring the heat gets distribute evenly.

If the heat isn't even, the test could yield incorrect results. And understanding the results isn't easy—it needs expertise about how materials and heat interact well.

We have been experts in thermal testing, developing innovative techniques and contributing to standard-setting in the industry. People have taken notice of us—prominent figures have us on their radar, and we've helped out on some major projects in aviation and automotive.

- Fatal mistakes in IPX9K waterproof test: nozzle size and water temperature control, the truth you must know

- Neutral Electrode Temperature-rise Tester: Ensuring Safety in Electrosurgery

- What are the implications for manufacturers transitioning from ISO 594 to ISO 80369-7?

- KINGPO Company Unveils Next-Generation Electrosurgery Analyzer

- KINGPO 2024 R&D Results Report

- ISO 594 is replaced with ISO 80369

- KingPo CEO invited to the 83rd International Electrotechnical Commission (IEC) General Assembly

- ISO 80369-7:2016 Connectors with 6% (Luer) taper for intravascular or hypodermic applications What is the ISO 80369-7 standard? What happened to ISO 594-1 and ISO 594-2?

- ISO 80369-3 Test Equipment LIst

- Understanding the Importance of Buying a Luer Connection Test Kit